To meet the necessary safety conditions, it is important that the operating parameters of technological systems do not exceed emergency values. If such situations occur, the automatic control system must immediately stop the operation of the equipment and not allow it to start until the troubleshooting or until the required process parameters of the regulated medium are reached.

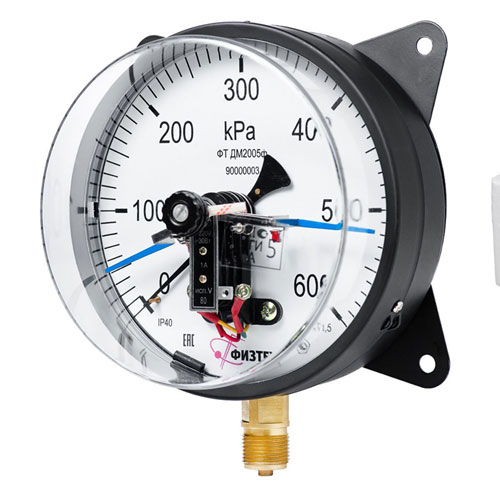

Today on the market there is a huge number of devices for controlling technological processes. For example, one of the sensors for measuring and controlling pressure is an electric contact pressure gauge.

Contents .

What kind of sensor and when it is used.

Electric contact pressure gauge - is a sensor used to measure gauge and vacuum pressures in different media (liquid, gas, steam), it is used as a direct-acting signaling device and allows to control production processes, with a special condition to the medium being the exclusion of its crystallization.

ECM is used to provide control signals to actuators that maintain the pressure values in the pipeline, as well as compressor units, hydraulic systems, pneumatic equipment or domestic autoclaves at a certain value.

The electric contact pressure gauge is popular in many industries and infrastructure systems:

- Energy;

- Metallurgy;

- Oil and gas and petrochemical industries;

- Water systems;

- Mechanical engineering systems;

- Heat generation and distribution.

ECMs are also in demand in the safety automation systems of thermal power plants, central heating plants and boiler houses.

Types of gauge models

Manufacture of electric contact pressure gauges engaged in a lot of manufacturers, some offer a fairly wide range of models, the following list is divided according to the different manufacturers:

- TM (TV, TMV), 10-series;

- PGS23.100, PGS23.160;

- ECM100Vm, ECM160Vm;

- TM-510P.05, TM-510P.06, DM2005Cr and its analog TM-610.05 ROSMA.

All of the above models are divided into pressure gauges with microswitches and with magnetic-mechanical contacts. Also, manufacturers produce devices in explosion-proof and vibration-resistant or liquid-filled (inside are filled with dielectric oil, most often with glycerin) to prevent the gauge pointer from "jumping" when the medium is subjected to high pulsations. The glycerin inside the ECM will prevent the needle from moving quickly.

Principle of operation of electric contact pressure gauges

The principle of operation of ECM is the closure or opening of a set point by a moving contact. The movable contact of an electric contact pressure gauge is a pressure indicating arrow, which rotates when the pressure in the measured medium changes. The set point (adjustable) value is set manually with the help of two arrows (min. and max.). These gauge hands are stationary after setting the values.

The value of the movable pointer is normally between the two setting pointers, but when the pointer crosses a threshold value the contacts of the internal electric circuit are closed or opened (depends on the version of the model). These contacts can be used in various relay circuits to control e.g. pneumatic or electromagnetic valves or magnetic starters of various motors.

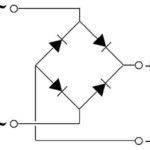

Please note! The switching capacity of the electrical contact pressure gauge contacts does not allow the switching of large load currents.

Each electric contact pressure gauge has a marking that describes all of its characteristics and varieties.

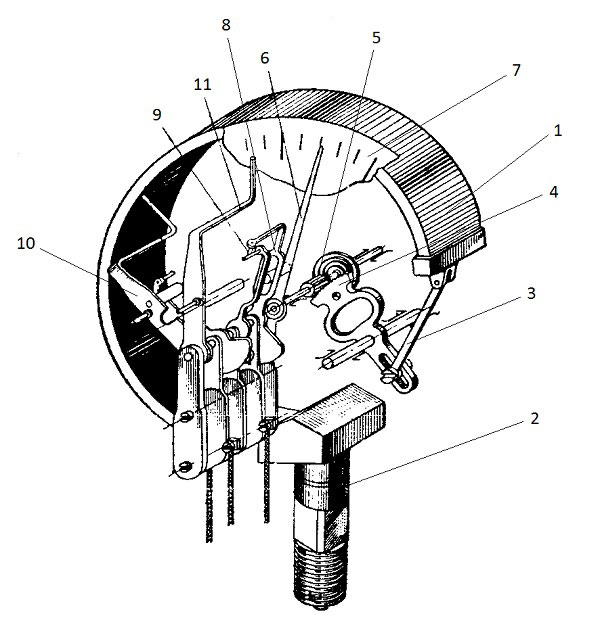

ECM Arrangement

The ECM is a cylinder-shaped device and is very similar to an ordinary pressure gauge. But unlike it, the ECM has two pointers for setting values: Pmax and Pmin (their movement is carried out on a dial scale manually). The movable arrow, showing the real value of the measured pressure commands the contact groups, which are closed or open when it reaches the set value. All pointers are on the same axis, but the places where they are fastened are isolated and not in contact with each other.

The axis of the indicator hand is isolated from the parts of the instrument, its case and scale. It rotates independently of the others.

Special current-carrying plates (lamellas), connected to the corresponding arrow, are led to the bearings by means of which the arrows are attached, and on the other side these plates are brought out to the contact group.

In addition to the above components, the ECM, like any gauge, also has a sensing element. In almost all models, this element is a Bourdon tube, which moves with the arrow permanently mounted on it, as well as in the role of this element for sensors measuring pressure medium over 6 MPa, use multi-coil spring.

Wiring diagrams of electric contact pressure gauges

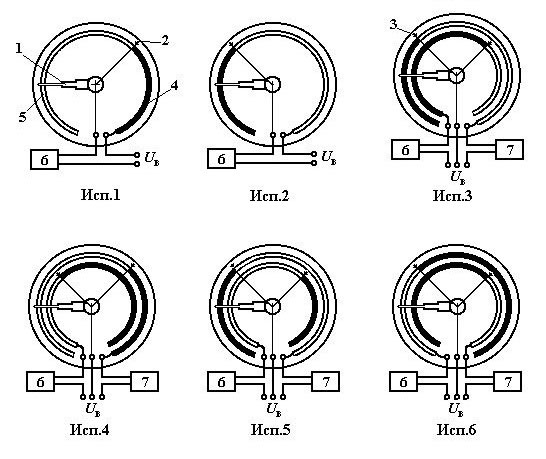

The figure shows typical possible connection diagrams of ECM.

- 1 - main indicating arrow;

- 2 and 3 - set points of limiting values;

- 4 and 5 - areas of closed and open contacts;

- 6 and 7 - external circuits in which the electric contact gauge is located.

Consider the operation of the ECM contacts by the example of the sensor with version 1. When the pressure reaches the set value (2) by the working arrow (1), i.e. when the working arrow (1) reaches the zone 4, the ECM contact closes. When the pressure drops below the set pointer (2), the contact opens.

What contact groups can be used depends on the type of the device, and according to GOST 13717-84 Appendix 1 they are of the following types:

- EXAMPLE 1 - Normally open (NO), with one contact;

- CONNECTION 2 - Normally closed (NC), with one contact;

- CONNECTION 3 - With two contacts, both normally closed (NC);

- CONNECTION 4 - With two contacts that are normally open (NO);

- CONNECTION 5 - With two contacts, one of them normally closed ( N.O.)N.O.) and the other normally open ( N.O.)N/O);

- CONNECTION 6 - With two contacts, one normally open ( N.O.) and the other normally open ( N.O.)NO) and the other one closed (NC).

Advantages and disadvantages

Like any technical device, ECMs have advantages and disadvantages.

The disadvantages are:

- Limitation of the load capacity due to too low a switching current limit, which has a range of 0.3 to 0.5 A (ECM with sliding contacts) up to 1 A (magnetic contacts);

- High cost, in comparison with pressure switches, the price can be two or three times higher.

Advantages:

- The visualization of the settings is clear and understandable;

- Setting the limits of operation is simple enough and does not require special keys, special knowledge and a lot of time;

- Assembled in a single housing that allows you to use no additional tees when connecting.

Manufacturers of ECM

The main and best known manufacturers of ECM sensors are:

- Teplokontrol;

- Teploklimat;

- WIKA;

- Teplopribor;

- Analytpribor;

- Expert;

- Manometer.

A brief overview of some models of sensors and their features

TM-510R.05, TM-510R.06

TM-510R.05, TM-510R.06 From the manufacturer CJSC "Rosma" are built on the basis of TM-510 gauges, and after installing the electric contact attachment, they become full-fledged EKM.

Magnetic push contacts are used in these models of ECM, which allow to switch high currents with high breaking capacity of contacts, in comparison with devices with sliding contacts.

ECM TM-510P.05, TM-510P.06 are characterized by a reliable electrical connection under dynamic loads.

Main characteristics:

- Two-pin electrical circuitry;

- Maximum possible voltage ~380 В;

- Maximum possible current 1 А;

- Maximum possible breaking capacity of the contacts 30 W;

EKM100Vm

EKM100Vm - is an electric contact pressure gauge on microswitches, designed to close or open an electric circuit when the set pressure limit is reached. It provides a visual indication of the monitored pressure.

Can be equipped with additional options if required:

- Tubes, bends or impulse tubes ;

- Cocks and valves;

- Gaskets, adapters, dampers, etc.

Model EKM100Vm has the following features:

- Range of possible measurements up to 4 MPa;

- Accuracy class 2.5;

- Body diameter 100 mm;

- V version by electric contact group according to GOST 2405-88.

Technology does not stand still, everything is improving, including the design of the measured devices.

For example, modern digital sensors EKM-1005, EKM-2005 from manufacturers Teploklimat, Teplokontrol and Elemer, very soon will replace outdated pointer devices. They are electronic indicating modern intelligent contact pressure gauges with both discrete and analog output (4-20 mA).

They are already in great demand on the market. So no matter what the characteristics of the device, sooner or later there will be a new, more convenient and useful in operation.

Related articles: