The thermostat is a simple device, which can be found in the cooling system of the car, in various household or climatic equipment, as well as in automation systems in industrial production.

Contents

What is a Thermostat

A thermostat is a discrete mechanical device that changes its state, or the state of its electrical contacts, when a specified temperature setpoint is reached.

These contacts can be used in relay circuits, for example, to start or stop various machines or to transmit information on reaching a temperature to an automatic control system. The word itself comes from two Greek words: "θερµο-" meaning heat and "στατός" meaning standing, stationary.

Unlike analog temperature sensors, such as thermocouple or resistance thermometer, a thermostat will not show the true temperature value at a particular point in time. Its only task is to "trigger", i.e. to change its state at a predetermined temperature value. Then, depending on the type of thermostat, the required control actions are carried out.

Thermostats are used in devices or systems that heat or cool to a predetermined temperature. For example, in refrigerators, heaters, car engine cooling systems, industrial furnaces, etc.

What does a thermostat consist of and what is its operating principle?

The structure of the thermostat and its principle of operation depend on the type of sensing element used. It can be a bimetallic plate or metal capsules with capillary tubes filled with liquid or gas.

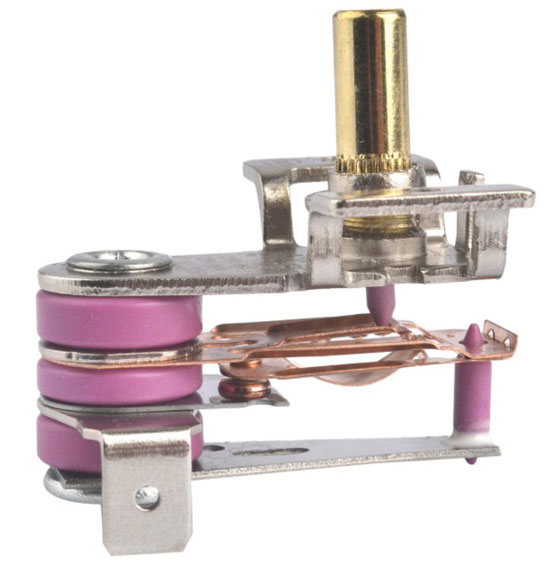

A bimetallic plate is two heterogeneous metal strips with different coefficients of thermal expansion, which are welded together. During heating, one of the metal plates expands more, which causes it to bend or straighten when it reaches the set temperature.

Moving mechanically in this way, the bimetal plate can close or open electrical contacts or open a coolant valve, for example.

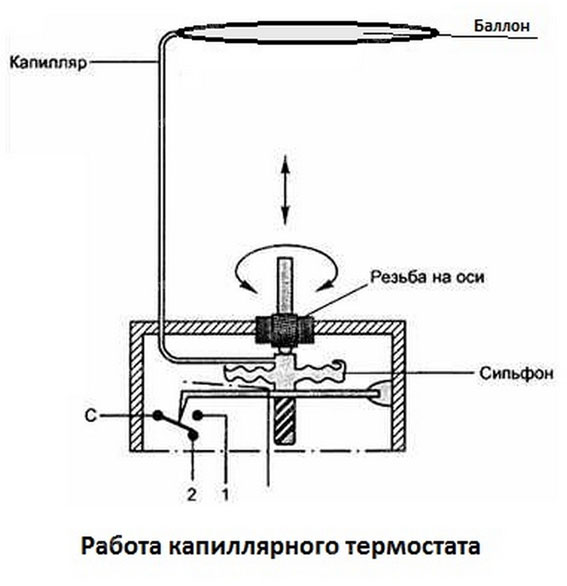

Another common type of thermostat is the capillary thermostat. Its operation is based on the first law of thermodynamics, according to which if the temperature in a thermodynamic system changes, it must perform mechanical work until it reaches an equilibrium state.

The capillary thermostat includes the following elements:

- A metal capsule containing the working fluid (e.g., glycol);

- A capillary tube that connects the sensor to the thermostat control unit;

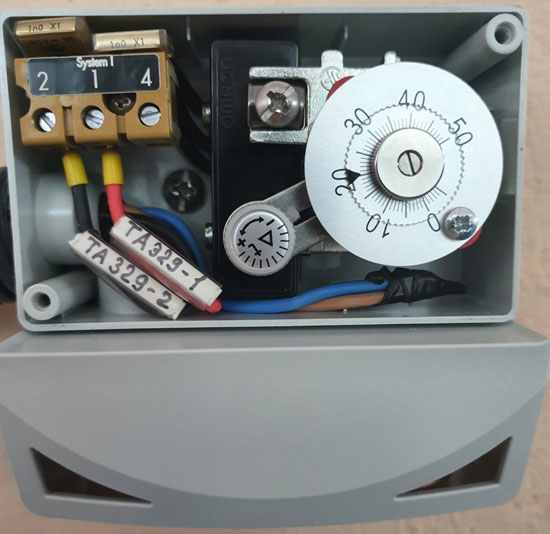

- Control unit or electromechanical relay with which the setpoint temperature is set.

When the metal capsule is heated, the volume of its contents changes, which presses on the membrane of the relay through a capillary tube and when the set temperature is reached, the contacts close or open.

The setting of the temperature is either made mechanically by turning a thermostat screw or the temperature is factory-set to a certain value.

Thermostat function

As mentioned above, the main purpose of a thermostat is to control the temperature. The range of applications for thermostats is very wide: from the iron in a small apartment to huge ovens in industrial facilities. They are used in a variety of appliances, heating systems, air conditioners, and household appliances.

The thermostat makes their use safe and at the same time comfortable, because the temperature is regulated automatically.

The thermostats can be built in or used additionally, e.g. in water faucets, for adjusting gas boilers or for heating floor heating.

An automotive thermostat is a must for the engine cooling system. It helps maintain the desired temperature, preventing overheating.

Types and types

Thermostats can be divided according to the range of operating temperatures:

- Devices that operate at high temperatures from +300 to 1200 ° C.

- Medium-level thermostats: from -60 to 500 °C.

- With the lowest temperature range (cryostats): Less than -60 °C. They work together with additional sources of cold.

Thermostats are also classified according to their stability and accuracy of operation. They are characterized by the deviation from the set temperature:

- 5 - 10 °C is the worst indicator of a thermostat.

- 1 - 2 °C is good for an air thermostat, but mediocre for a liquid thermostat.

- 0.1 °C - excellent for air thermostat, average for liquid thermostat.

- 0.01 °C - not achievable for air thermostat, good for liquid thermostat of special design.

- 0.001 °C - only achievable in metrological liquid thermostats.

How to Test a Thermostat

The following method can be used to test the thermostat: When changing the temperature set point, you should hear a characteristic click when passing the ambient temperature value - the contacts close and open.

If the thermostat is removable, you can try to heat its sensing element and check the operation.

If, for example, you consider the thermostat in the oven, then by setting a certain temperature, after heating you can observe the flame of the burner: if it has decreased and remains at the same level, then everything is fine. The accuracy of the result obtained can be achieved by using a thermometer.

Correct operation of the thermostat setting can be checked using a thermometer or multimeter with a thermocouple. This method is suitable, for example, for a washing machine. Also help the tester, which is connected to the contacts of the thermostat will show their shorting and breaking.

What may be the thermostat malfunction

The main faults of this device of all varieties - it is constantly closed or open contacts, regardless of the temperature readings. Another of the faults is a large error, that is, the temperature readings do not match the setpoints.

Thermostat and thermostat regulator - what is the difference

Thermostats are a more capacious concept. Thermostats are part of them.

Modern thermostats have analog inputs from sensors, with the ability to display the measured temperature on the display and analog and discrete outputs to control the technological process. Have the ability to record the measured parameters in the memory and display the graph of the control process.

The task of the thermostat is much simpler - to switch contacts at the set temperature value.

Related articles: