Decorative or basic lighting with LED strips LED strips have recently become widespread. Since these strips are powered by DC voltage of 12V (less often 24V), it is important to choose the right step-down transformer or, as it is also called, power supply for a long-lasting and correct operation of such lighting. In this article, we will consider the basic criteria for selecting such a device.

Main technical parameters of the power supply of LED strip

LED strip power supply – step-down transformerwhich converts the AC voltage of 220 volts to DC voltage with a value of 12 or 24 volts. Power supplies for such lighting devices come in pulse version, which are based on transforming the input voltage into high frequency pulses, so that the DC voltage at the output has high-quality rectification. Such devices have a sufficiently high efficiency, compact size and good technical characteristics.

Output Voltage PSU

Because of the peculiarities of design, manufacturers of LED tapes produce devices with a supply voltage of 12 or 24 volts DC. Sometimes, for very powerful strips use a voltage of 36 volts, but this is rather an exception. An important rule when selecting a transformer is that the output voltage from it must match the voltage of the LED strip.

How to calculate the power supply for the LED strip

The most important characteristic, after voltage, for the selection of a transformer for a particular light-emitting strip is the power. This parameter of the power supply must be higher than the power of the LED strip by at least 20 percent. Usually, the power of electrical appliances is indicated on its case. LED strips and transformers are no exception. But it so happens that the LED strip is not specified this characteristic and, therefore, it may be difficult to calculate the required power supply.

It is important to understand that the power LED strip depends on the type of LEDs, the density of their mounting on the strip and its length.

Different types of matrices have different power values, which can vary significantly. For example, popular LEDs have the following powers:

| LED | 3528 | 5630 | 5050 | 2835 | 5730 |

|---|---|---|---|---|---|

| LED power, W | 0,11 | 0,5 | 0,3 | 0,2 | 0,5 |

Please note! The numbers in the brand of LED indicate its size in millimeters, for example, 3528 - 35 mm by 28 mm.

Knowing (or by calculating) number of diodes per 1 meter of strip, you can calculate the power for its entire length. For convenience, have long been calculated and are freely available tables with the power of each type of tape, focusing on these tables can be correctly and easily select the power supply for the LED strip.

| Type of ribbon | LED density per 1 meter | Power of 1 meter strip | Power of 5 meters ribbon |

|---|---|---|---|

| SMD3014 | 60 pcs | 6,0 W | 30W |

| 120 pc | 12,0 W | 60W | |

| 240 pcs | 24,0 W | 120 W | |

| SMD3528 | 30 pcs. | 2,4 W | 12 W |

| 60 pc. | 4,8 W | 24 W | |

| 120 W | 9,6 W | 48 W | |

| SMD5050 | 30 pcs. | 7,2 W | 36 W |

| 60 pc. | 14,4 W | 72 W | |

| SMD5630 | 30 pc. | 6,0 W | 30W |

| 60 pc. | 12,0 W | 60 W |

Strengthening the above, determine the following sequence of calculation and selection of the transformer for the LED strip:

- Select the light-emitting strip and calculate the required length;

- Find out the matrix of LEDs (visually or from the user manual) and the density of their installation on the strip;

- Calculate the power of a meter tape;

- Multiply the received power of 1 meter by the final value of the tape length;

- Get the power rating of the transformer.

- Take into account the power reserve factor (see below), multiply by the rated power and get the required power of the device.

For example, we have a 12 V LED strip, 3 meters long, with SMD LEDs 5050, the number of LEDs on 1 meter - 60 pcs. Power consumption of 1 meter of tape is about 15 W, so 1 meter = 15 W. Then 3 m = 15 W * 3 = 45 W. Multiply by the safety factor of 20% and you get that we need a power supply for 45 W * 1,2 = 54 W. The current consumption of this LED strip will be 54 W / 12V = 4,5 A.

Power reserve factor

To correctly calculate the power supply you need to consider another factor. If you choose a power supply with power equal to the LED strip, it will heat up and this can not only reduce the service life, but also, in case of poor-quality assembly, lead to a fire. Therefore, when buying a transformer for the LED strip must take into account the power reserve for the device. Usually choose a device with a capacity 20% higher than the power consumption of the LED strip. Power reserve is guaranteed to protect you from overheating of the device and will allow you to operate the power supply for a long time and without problems.

Dimensions

Power supplies come in different shapes and sizes. Most often the power of the device determines its overall dimensions. The higher the power, the larger the device. Also powerful devices have a fan to cool the device during operation, and this greatly increases the size and installation requirements.

In order to hide several sections of ribbon, it is best to choose several small power supplies rather than one large one. It will be a little more expensive, but this way you can safely hide the power supplies in the structures and distribute the load on several devices.

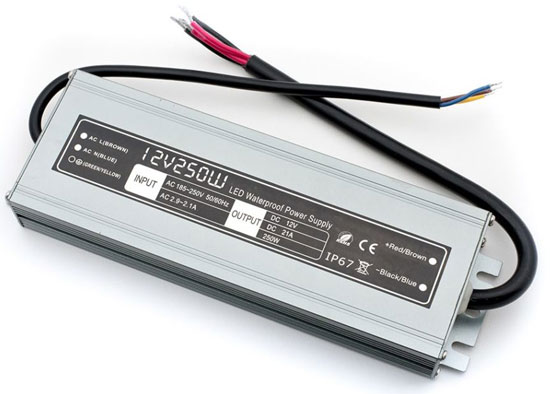

Protection degree against penetration of moisture and dust

Power supplies, as well as LED tapes, made in versions for different environments and have different degrees of protection from moisture and dust. When choosing a transformer must take into account the influence of the environment on the device. For example, when used in residential areas with normal humidity protection IP20 - IP40 is sufficient. If you plan to install the power supply unit outdoors, you should buy a device with IP67 protection against precipitation. Classification by quality of protection against moisture and dust is the same for all electrical appliances and devices, so it is not difficult to find it.

If the power supply capacity is high enough, in devices without moisture and dust protection, a fan will be used for cooling. It generates a certain level of noise during operation. If the noise of the device is unacceptable for the assigned tasks, it is better to choose a moisture-proof device, which will have passive cooling.

Availability of cooling

With the correct calculation of the power supply unit on the power of the connected LED strips, it will not heat up, and will function steadily and safely. But still, if the power is too high, then overheating is possible. To eliminate the negative impact of high temperatures on the device in its design provides a cooling system. It can be active or passive.

For active cooling, a fan is mounted in the device case, and such power supplies cannot be made in a moisture-proof design due to the need to circulate air inside the device and exchange with the environment. Such transformers emit noise from the fan and have increased power consumption, which are negative qualities. But it is worth noting that active cooling is the most effective way to reduce the temperature of the device.

Passive cooling is structurally performed in the form of special metal radiators, which are installed in places where the greatest heat occurs on the device board. Also, passive cooling takes place due to the metal housing of the devices, both in moisture-proof and conventional version.

Additional features

Power factor correction

Power supplies sometimes specify the presence of power factor correction in their specifications. In the documentation of the device it is referred to as PFC or Power Factor Correction. This means that the power supply has high technical characteristics in terms of energy savings and useful use of the consumed power. Moreover, such transformers allow grouping them without special starters and are environmentally friendly due to their high efficiency.

Enclosure material

The housing of the device can be made of plastic, aluminum or other metal. Aluminum housing is used not only to reduce the weight of the device and protect it from damage, but also for passive cooling of the power supply. The metal case also protects against mechanical effects and cools the device, but it weighs considerably more than the aluminum case. Plastic material for the housing is used in devices that will be used with low-power LED strips and without the likelihood of damage.

The presence of RGB-controller

To connect and use RGB and RGBW ribbons is not enough to buy only a step-down power supply. In this case we need another RGB strip controller, which allows you to change the hue of the light strip using various control devices (remote control, display, etc.). Some power supply units come with such controllers and are designed exclusively for multicolor ribbons. They are more expensive than conventional transformers. For one-color versions of LED strips the use of the controller is not required.

Related articles: