Without this electrotechnical device, electricity consumers would not be able to charge car batteries, connect energy-saving light sources. The electrical product reduces the stationary voltage to the required level. The device is based on electromagnetic induction. Sold in specialized stationary retailers, online stores.

Contents

General structure and principle of operation

The step-down transformer from 220 to 12 volt is purchased by drivers, cottagers, owners of country houses, cottages for the device of in-house low-voltage lighting network. Sometimes it is not economically viable to use 220 volt power in the home.

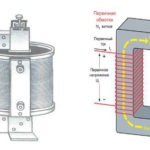

The product consists of four main parts: two core rods and two coils of copper wire of the required cross section and length. They are called windings containing an unequal number of turns. The core rods are made of special steel used in the electrical industry. The 220 transformer is supplied with the current of the stationary power grid.

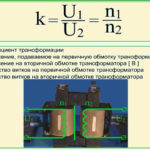

In the primary winding an intensive movement of electrons begins, an electromotive force is created. A magnetic field is formed, which is crossed by the second coil. Electric potentials appear in it, because the magnetic field of the first coil causes self-induction (movement of electrons) in the second coil. A difference in electrical levels arises, tending to equalize the potential values to zero.

The overflow of electrons from high potential to final zero potential gives rise to electric current. The voltage in the secondary winding depends on how many times fewer turns it has than in the first winding. It should be remembered that the step-down electrical device generates an alternating voltage in the end winding with a polarity change 50 times per second. You also get direct current by connecting a rectifier into the system to have 12 volts of direct current at the output.

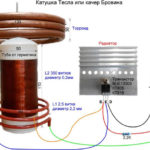

There is a wide range of electronic step-down products that do not contain cores, coils.

Reducing devices are microscopic electronic circuits in connection with capacitors, resistors and other important elements. Compared to traditional current converters, they have undeniable advantages:

- in compactness;

- in weight;

- manual adjustment of the undervoltage;

- quiet operation;

- high efficiency.

The buyer can choose the transformer he needs. It is his right.

Made by his own hands transformer is recommended to operate, hiding it behind the walls of a metal or wooden case with natural ventilation.

How to choose a step-down transformer

Imported electrical appliances, operating from 110 volt mains, are now on sale. Domestic power grids supply 220 volts of current. It is problematic to use a foreign household or other device. But there is a way out. You can purchase a 220 volt transformer with 110 volt step-down terminals.

When selecting a step-down product, it is important to calculate the maximum load for which it is rated. The result is obtained by the following method. Multiply the volts by the amperage and you get the power. The formula looks like this: V x A=W. Select a high-power consumer of electrical energy, calculate the peak load according to the formula, add 20% to its value.

Here is an example. A housewife has bought an imported food processor, working from a 110 volt mains, rated at 3 A. Multiply the figures. We get a power of 330 W. This is the standard power at which the combine works. But while making a dressing, for example for borscht, a bone got into the machine, which the device must grind. In a second, the power will jump to 1400 W. The manufacturer of the appliance specifies the maximum power in the data sheet.

A device that reduces the current is not difficult to make yourself. The algorithm is as follows: calculate the number of turns of metal wire on the coils. The calculation of the primary begins with a 220 volt winding. After the calculations determine the number of turns. We get 2200 turns with a wire cross section of 0.3 mm and a rod area of 6 sq. cm.

After calculating the number of turns for a 12 volt coil. The second coil, producing a voltage of 12 volts, will have 120 turns with a wire section of 1 mm. The number of turns in one coil should not equal the number of turns in the other coil. Ideally, they can if the copper wire has different cross sections.

Voltage of twelve volts are powered by LED strips, lamps, halogen lighting. Halogen bulbs require a small amount of power. An important point is the manufacture of the core. Its quality determines the power of the transformer.

If there is no special electrical steel at hand, metal containers from beer, bread kvass, and other liquid products are used. From the cans are cut into strips 3 dm long and 0.2 dm wide. Blanks subjected to firing, after removing scale. Varnish, wrapped with paper on one side.

The second winding is filled with wire with a cross section of 1 mm. Reel base is made of cardboard material of higher strength. Wrap the cardboard blank with paper soaked in paraffin. On the prepared cores wind the wire, not forgetting to separate the wound coils with paper. Ready to use windings are fixed on a compact wooden or metal frame. Fix it with staples or other fasteners.

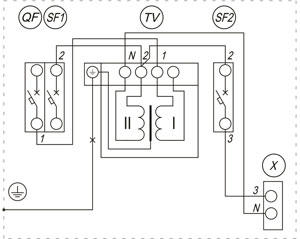

Wiring diagram for a step-down transformer

How to connect a transformer 220 to 12 volts, many people are interested. Everything is done simply. Cues the algorithm of actions marking in the places of connection. The terminals on the connection panel are marked with Latin letters for the connection to the contact wires of the consumer unit. Terminals to which the neutral wire is connected are marked with N or 0. The power phase is marked with L or 220. The output terminals are marked with 12 or 110. It remains not to confuse the terminals and by practical actions to answer the question of how to connect the step-down transformer 220.

Factory labeling of the terminals ensures safe connection by a person not familiar with such actions. Imported transformers are subjected to domestic certification control and are not dangerous in operation. Connect the product for 12 volts according to the principle described above.

Now it is clear how to connect a factory-made step-down transformer. It is more difficult to determine with a homemade device. Difficulties arise when they forget to mark the terminals during the installation of the device. To make a connection without error, it is important to learn how to visually determine the thickness of the wires. The primary coil is made of wire with a smaller cross section than the end action winding. The wiring diagram is simple.

It is necessary to learn the rule, according to which it is possible to receive increasing electric voltage, the device is connected in reverse (mirror version).

The principle of the step-down transformer is easy to understand. It is empirically and theoretically established that the electron level coupling in both coils should be evaluated as the difference of the magnetic flux, which creates contact with both coils, to the electron flux, which occurs in the winding with a smaller number of turns. By connecting the end coil, one finds that a current appears in the circuit. That is, you get electricity.

And this is where the electrotechnical collision arises. It is calculated that the energy supplied from the generator to the primary coil is equal to the energy directed into the circuit created. And this happens when there is no metallic, galvanic contact between the windings. Energy is transferred by creating a powerful magnetic flux, which has variable characteristics.

In electrical engineering, there is a term "dissipation". The magnetic flux loses power along the way. And this is bad. Corrects the situation by a design feature of the transformer device. Designed metal magnetic ways do not allow the magnetic flux to dissipate through the circuit. As a result, the magnetic fluxes of the first coil are equal to the values of the second coil or almost equal.

Related articles: