To measure the temperature of various surfaces use different sensors, including a pyrometer. It works pretty simple and fast. And what is a pyrometer, let's understand.

Contents

What is a pyrometer?

A modern engineering device for determining the temperature of any object, based on an infrared sensor, is called a pyrometer. It's also known by the names temperature detector, temperature data logger, digital thermometer or infrared gun. The operation of the device is based on the principle of determining the temperature value of the surface of an object by the thermal electromagnetic radiation electromagnetic heat radiation from the surface of the object. The pyrometer picks up invisible infrared radiation, converts it into degrees, and displays the result on the display. Non-contact and fast method of examining necessary objects allows specialists to avoid possible injuries.

Area of application

Rather wide application of pyrometers is found in those productions where a large number of heating devices is installed. In the field of construction and heat engineering they are used to calculate the heat loss of structures, including pyrometer helps to identify damage to the insulation.

In industry such devices make it possible to analyze the temperature of all kinds of processes remotely. This is necessary, for example, in mechanical engineering, metallurgy and other industries.

For example, electricians check heating levels at the connection points of wiresand car mechanics check the heating of car parts. Scientists can use pyrometers during various research or experiments to determine the correct temperature of substances and bodies.

In everyday life, people use such devices to determine the temperature of the body, water, food, etc.

Types and classification

Depending on the functional attribute, there are several classifications of pyrometers.

According to the essential method used in the work:

- Infrared;

- Optical.

Optical pyrometers are subdivided into:

- Bright;

- Color, or multispectral.

According to the way of aiming there are devices with optical or laser sights.

According to the coefficient of radiation used there are pyrometers with variable and fixed coefficient.

According to the possibility of transportation pyrometers are divided into stationary and mobile (portable).

Based on the possible range of measurements distinguish:

- low-temperature (-35 ... -30 ° C);

- high temperature (+400 ° C and above).

Structure and principle of action

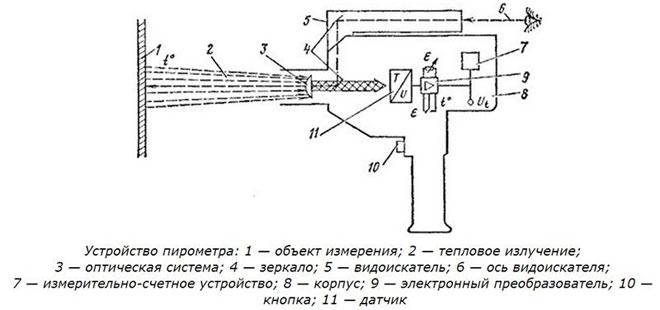

Infrared radiation detector is the basis of pyrometer structure. The data is converted by the integrated electronic system and shown on the display.

The typical pyrometer is shaped like a pistol with a small display. The compact control panel, laser aiming and high accuracy in close contact with the object explain the demand for the instrument among engineering and technical workers.

The main working elements of the pyrometer are the lens, the receiver, and the display, on which the measurement result is displayed. The principle of pyrometer functioning is the following: infra-red radiation comes from the investigated object and it is focused by the lens and sent to the receiver (thermopile, semiconductor, thermocouple).

If a thermocouple is used, the voltage changes when the receiver is heated. Resistance is in the case of semiconductors. These changes are converted into temperature readings.

In order to make a measurement you just need to point the pyrometer at the object, actuate it and mark the obtained result. Using a special button you can adjust the temperature measurement format - Celsius or Fahrenheit.

Technical Specifications

The pyrometer has a number of parameters that characterize its functionality. Selection of the desired model of the device is carried out according to their values. Let's turn to the main ones.

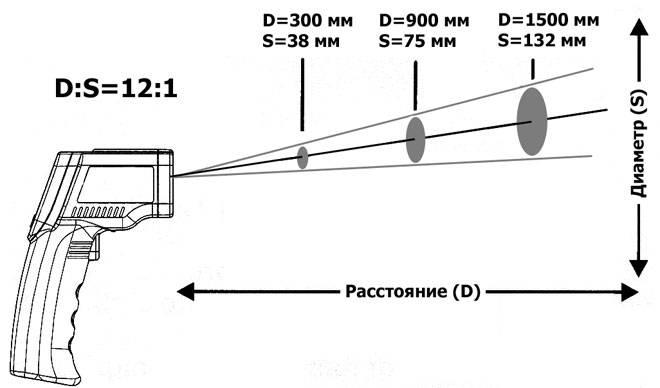

Optical resolution

This is the ratio of the diameter of the spot of the instrument to the distance to the object. This function depends on the angle of the device lens: the larger it is, the larger area it will be able to cover. The most important factor in the accuracy of the measurement is the overlay of the spot solely on the surface material. If the area is exceeded, the measured value is likely to be inaccurate.

TIP. Each pyrometer model has a different optical resolution. The difference between them is impressive, e.g. from 2:1 to 600:1. The latter ratio is typical for professional devices. As a rule, they are used in heavy industry. The optimal value for household and semi-professional pyrometers is 10:1.

Working range

Range of the device depends on the pyrometric sensor, and often ranges from -30 ° C to 360 ° C. So, for domestic use almost all types of pyrometers will be suitable, given the maximum temperature of the coolant in the heating system up to 110 ° C.

Accuracy

Accuracy assumes the level of possible deviations of temperature values and depends on the accuracy of the pyrometer. On average, acceptable deviations are no more than 2% of the norm.

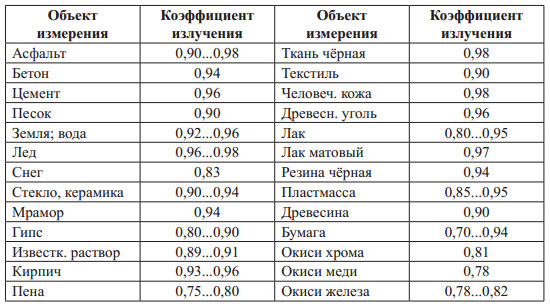

Radiation coefficient

This parameter is the ratio of the current temperature radiation power to that of a reference black body.

REFERENCE. For matte materials, the emissivity coefficient is 0,9-0,95. For this reason, more devices are adjusted to this value. The result will be markedly different from the real one, for example, in the case of measuring the surface heating of shiny aluminum.

In order to measure more accurately, many models are equipped with a laser pointer. In this case, the light beam is not placed in the center, but indicates the optimal boundary of the measurement area.

Advantages and disadvantages

Like any other device, the pyrometer has its advantages and disadvantages. Their presence is explained by the nuances of the device and the conditions of application.

Advantages

- Mobility, small size and very simple design;

- Affordable low cost, due to the use of a minimum number of elements in the design;

- High level of reliability;

- Wide enough measurement range.

Minuses

- Direct dependence of pyrometer readings on the emissivity of the examined object;

- Accuracy of measurement results may be lower due to the peculiarities of the physical state of the surface of the object;

- The function of correcting the readings and establishing the error is provided only on the newest devices;

- Distance plays a large role in the accuracy of the measurement.

The most popular models are

EOP-66

The EOP-66 pyrometer is used for scientific and laboratory researches. It is designed to measure the indicators of surfaces of objects at temperatures from +900 to +10000 ° C,

This stationary model is equipped with a telescope which consists of an objective lens and an ocular microscope. The two-lens lens has a focusing range of up to 25.4 cm and an optical resolution of 3:1. Note: the telescope of this instrument is fixed to the base and moves smoothly in the horizontal plane.

Kelvin IKS 4-20

This is a pyrometer of high accuracy, which has a universal spectrum of temperature readings: from -50 to +350 ° C, a very high speed of action - 0.2 s. Application of the instrument is provided in the range of 8-14 microns.

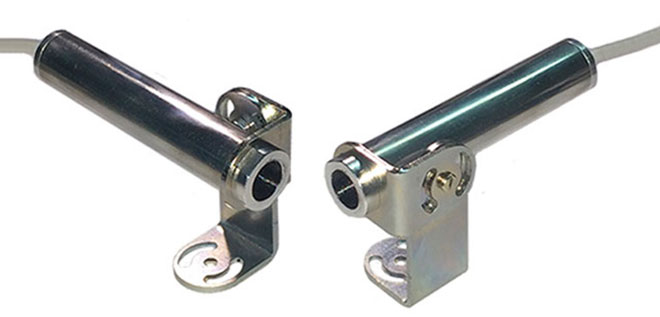

This pyrometer combines the capabilities of both mobile and stationary device. This is due to the compact size (17x17x22 cm) and the presence of planting socket lens mount M12. The manufacturer guarantees absolute water- and dust-tightness. So, the presented pyrometer model is possible to use in complex industrial and construction industries.

S-700 "Standard"

This non-contact device is preferably used in e.g. construction or metallurgy. It serves well as an infrared detector for determining the degree of surface heating of bulk and solid objects as well as molten and fluid materials.

The temperature range ranges from +700 to + 2200 °C, which is typical for high-temperature devices. Interaction with external media is enhanced through two different output interface options: analog output 4 - 20 mA or digital RS-485.

BACKGROUND. The optical pyrometer can be purchased at a very affordable price: the minimum cost of such a device is 6000 rubles, the maximum cost is 30000 rubles.

How to measure temperature correctly with a pyrometer

After purchasing the device it is necessary to carefully study its manual. Despite the very simple operating requirements, reckless actions can lead to significant distortions of temperature values. The process for properly measuring the temperature with a pyrometer is as follows:

- Turn on the pyrometer instrument;

- Determine the material of which the object is made (e.g., steel or copper);

- Then, depending on the model of the instrument, enter the radiation coefficient as an edit on the display;

- Direct the beam of the infrared pyrometer to the surface to be measured;

- Determine the measurement spot boundary using the laser pointer.

With this sequence of measurements you will get the results closest to the actual temperature.

The pyrometer is a versatile and indispensable instrument in its functionality. Once you understand the nuances of its operation, it can be easily used both in the professional sphere and in everyday life.

Related articles: