The resistance of any conductor is generally dependent on temperature. The resistance of metals increases with heat. In terms of physics, this is explained by an increase in the amplitude of the thermal vibrations of the elements of the crystal lattice and an increase in resistance to the directional flow of electrons. The resistance of electrolytes and semiconductors decreases when heated - this is explained by other processes.

Content

Thermistor Principle

In many cases, the phenomenon of resistance vs. temperature is detrimental. For example, a low resistance of the filament of an incandescent lamp when cold causes it to burn out when switched on. Changing the resistance value of permanent resistors when heated or cooled leads to changes in circuit parameters.

Developers are fighting this phenomenon by producing resistors with a reduced TCR - temperature coefficient of resistance. Such elements are more expensive than conventional ones. But there are such electronic components, in which the dependence of resistance on the temperature is pronounced and normalized. These elements are called thermoresistors or thermistors.

Types and Design of Thermistors

Thermistors can be divided into two large groups according to their reaction to changes in temperature:

- If the resistance drops when heated, such thermistors are called NTC thermistors (with a negative temperature coefficient of resistance);

- If resistance increases when heated, then the thermistor has a positive TCS (PTC-characteristic) - such elements are also called posistors.

The type of thermistor is determined by the properties of the materials from which the thermistors are made. Metals increase resistance when heated, so on their basis (or more precisely, on the basis of metal oxides) are produced thermoresistances with a positive TCS. Semiconductors have the opposite dependence, so they are used to make NTC-cells. Thermostatic elements with negative TKC can theoretically be made on the basis of electrolytes, but this variant is extremely inconvenient in practice. Its niche is laboratory research.

The design of thermistors can be different. They come in the form of cylinders, beads, washers, etc. with two leads (as in conventional resistor). You can choose the most convenient form for installation in the workplace.

Main characteristics

The most important characteristic of any thermistor is its temperature coefficient of resistance (TCR). This indicates how much the resistance changes when heated or cooled by 1 degree Kelvin.

Although the temperature change expressed in degrees Kelvin is equal to the change in degrees Celsius, thermoresistors are still characterized in Kelvin. This is due to the widespread use of the Steinhart-Hart equation in calculations, and it includes the temperature in K.

The TCS is negative for NTC type thermistors and positive for posistors.

Another important characteristic is the resistance rating. This is the resistance value at 25 °C. Knowing these parameters, it is easy to determine the applicability of a thermistor to a particular circuit.

Also important to the use of thermistors are the nominal and maximum operating voltages. The first parameter determines the voltage at which the element can operate for a long time, while the second parameter determines the voltage above which the performance of the thermistor is not guaranteed.

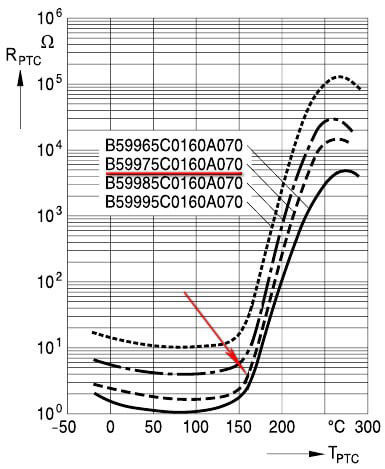

For posistors, an important parameter is the reference temperature - the point on the resistance-heat diagram at which the characteristic fracture occurs. It determines the operating range of PTC resistance.

When selecting a thermistor it is necessary to pay attention to its temperature range. Outside of the specified by the manufacturer area, its characteristic is not standardized (this can cause malfunctioning of the equipment) or the thermistor is not functional there at all.

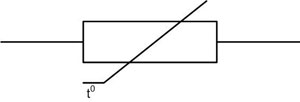

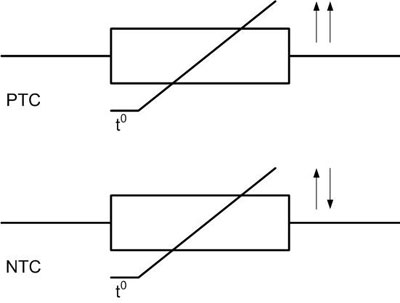

Figure 1.

In the schemes of the thermistor's CSR may differ slightly, but the main feature of thermistor is the symbol t next to the rectangle for the resistor. Without this symbol it is impossible to determine what the resistance depends on - similar UGOs have, for example, varistors (resistance is determined by the applied voltage) and other elements.

Sometimes an additional symbol is put on the UGO, which defines the category of the thermistor:

- NTC for cells with a negative TCS;

- PTC for posistors.

This characteristic is sometimes indicated by arrows:

- unidirectional for PTC;

- Multidirectional for NTC.

The letter designation may be different - R, RK, TH, etc.

How to Test a Thermistor for Functionality

The first test of a thermistor is to measure the nominal resistance with an ordinary multimeter. If measured at room temperature, which is not very different from +25 ° C, then the measured resistance should not differ significantly from that indicated on the case or in the documentation.

If the ambient temperature is higher or lower than the specified value, a small correction must be made.

You can try to take the temperature characteristic of the thermistor - to compare it with the one given in the documentation or to reconstruct it for an element of unknown origin.

There are three temperatures available to create with sufficient accuracy without measuring instruments:

- melting ice (can be taken from a refrigerator) - about 0 °C;

- the human body - about 36 °C;

- boiling water - about 100 °C.

According to these points you can draw an approximate dependence of resistance on temperature, but for posistors it may not work - on the graph of their TCS, there are areas where R is not determined by temperature (below the reference temperature). If a thermometer is available, you can take a characteristic by several points - lowering the thermistor in water and heating it. Every 15...20 degrees you need to measure the resistance and mark the value on the diagram. If it is necessary to read parameters above 100 degrees, oil (e.g. car oil or transmission oil) can be used instead of water.

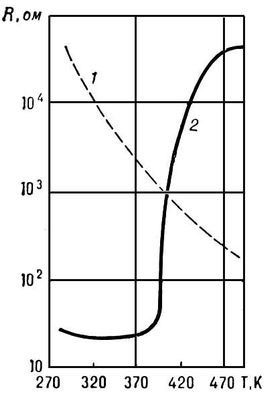

The figure shows typical temperature dependencies of the resistances: solid line for PTC, dashed line for NTC.

Where to use

The most obvious application of thermistors is as temperature sensors. Both NTC and PTC thermistors are suitable for this purpose. You just need to select the element according to the working area and take into account the thermistor characteristic in the measuring device.

You can build a thermal relay - when the resistance (more precisely, the voltage drop across it) is compared with a predetermined value, and when the threshold is exceeded, the output is switched. Such a device can be used as a thermal control device or a fire detector. The creation of temperature meters is based on the phenomenon of indirect heating - when the thermistor is heated by an external source.

Also, direct heating is used in the use of thermistors - the thermistor is heated by the current flowing through it. NTC resistors in this way can be used to limit current - e.g. when charging capacitors with high capacitance when turned on, as well as to limit the starting current of motors, etc. Thermal-dependent elements have a high resistance when they are cold. When the capacitor is partially charged (or the motor is at nominal speed), the thermistor has time to heat the flowing current, its resistance will drop, and it will no longer affect the operation of the circuit.

In the same way, you can extend the life of an incandescent lamp by including a thermistor in series with it. He will limit the current at the most difficult moment - when the voltage is turned on (this is when most bulbs fail). After it has warmed up, it will no longer affect the lamp.

In contrast, thermistors with a positive characteristic are used to protect electric motors during operation. If the winding current rises due to a motor jam or an excessive shaft load, the PTC resistor will heat up and limit that current.

Thermistors with a negative PTC can also be used as heat compensators for other components. For example, if you install a NTC thermistor in parallel with a transistor mode-setting resistor with a positive TCR, the temperature change will affect each element in the opposite way. As a result, the temperature effect is compensated, and the operating point of the transistor will not shift.

There are combined devices called indirectly heated thermistors. Such an element has a temperature-dependent element and a heater in the same housing. There is thermal contact between them, but they are galvanically isolated. By changing the current through the heater, the resistance can be controlled.

Thermistors with different characteristics are widely used in technology. In addition to standard applications, their scope of work can be expanded. Everything is limited only by the imagination and qualification of the developer.

Related articles: