Manufacturers now produce many types of drills. Cone drill is very popular, which is used in construction and installation work. A variety of tapered products is the stepped metal drill, which can make holes of different widths.

Contents

Cone drill bit for metal

The various cone drills for metal are not difficult to use. The working part of this tool is a tapered row, consisting of staggered ring elements and a longitudinal groove, which has a sharp edge for cutting metal. Therefore, it is possible to use the same tool to make different holes. By choosing such a product, the craftsman will not have to look for tools of different thicknesses in the process of work. You will not have to buy them, which will save on the production of installation work.

Gradual change in the diameter of the tapered tool is carried out due to the presence of smooth transitions from the wide part of the product to the tip. This shape helps the product to rotate, resulting in more efficient machining of thin metal. Tapered models use strong steel, so the product has a long service life and will not have to be sharpened often.

Cone drill bits are capable of performing such technological processes in one go, for which several models need to be applied in stages when using other types of designs. It is possible to drill holes in metal sheet with great speed, the processing quality is excellent, even if the sheet has a small thickness. Conical metal drills are used to process steel sheets, non-ferrous metals, wood, plastic or plaster.

The tip of the tapered tool ensures accurate installation of the fixture, it is not necessary to punch an approximate hole in the workpiece. The taper drill is mounted on a hand drill or machine tool. If you pick up adapters, such a device can be mounted on a bolt drill or a rotary hammer. The design with an adapter allows you to drill holes in workpieces made of steel.

Tools are used to fix defects after using a drill, to eliminate burrs, to perform triangular holes. The tapered tool has a tip. In order to carry out pre-drilling, there is a beveled transition. To remove uneven holes, there is a cutting edge, with its help you can increase the width of the opening. Tools are often used in the car service when repairing assemblies of cars, installing plumbing fixtures, repairing electrical panels, in construction.

Step drill for metal

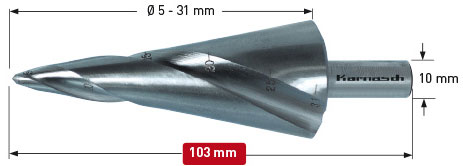

Devices with such a design allow you to choose the diameter of the hole. Products have a cone shape with a sharp end. Stepped metal drills contain a taper in the form of a spiral transition with a number of circular steps of different diameters.

The cutters have great strength, this increases the durability of the product. Step drill is a type of cone-shaped tool. The design of the stepped tool is different in that the increase in thickness is carried out in the form of steps, on which the diameter is marked, which facilitates drilling, makes it possible not to make constant measurements of the width of the opening. The limit of sheet metal thickness is indicated on the product. If the sheet is very thick, it is processed on both sides.

Advantages of a stepped tool:

- Allows the exact diameter to be observed;

- It is not necessary to make additional processing of the made hole;

- with the help of 1 tool makes a hole with a diameter of 4 to 40 mm;

- Can work metal with a thickness of 1 mm;

- grinds the edges of the opening, which has been cut with a standard tool;

- make the bevel of the product;

- can be mounted on a machine or hand drill.

Sometimes it can cause misalignment. To avoid this, it is necessary to follow the operating instructions and carefully monitor the operation of the device. Step drills make openings of different diameters in workpieces made of steel, non-ferrous metal.

The step device is used in various situations:

- when carrying out various repair works;

- in landscape design;

- in the industrial production process;

- in the construction and installation of structures;

- heating installation;

- installation of plumbing;

- work on the house;

- apartment repair.

The stepped device is effectively used in smoothing deformations or grinding burrs, which gives the use of other tools.

Why an electrician needs a step drill for metal

A step drill can be used by an electrician. He needs this device when installing electrical wiring. For example, an electrician has to drill a hole in a steel profile in order to run a wire inside a plasterboard cladding. The thickness of the metal profile is sometimes up to 0.5 mm. The diameter of the cable to be passed is 16 mm. It is difficult to drill this profile with a simple tool, as the holes will come out uneven. Multistage version can make a hole in the workpiece with a thickness of 16, 20, 25 mm.

Step drills are necessary for the electrician to work in electric boards. It is often necessary to drill an opening in the shield to install control buttons, indicators, various switches, fittings or a lock. Electric panel has a thickness of 1 mm. Mounting the gland on the shield requires you to drill a large width hole in the shield.

Stepped product perform apertures in cable boxes made of metal for the output of the wire. If the box openings for the wire outlet are fixed rigidly, then you must make an additional hole to mount the gland and plug.

What to pay attention to when choosing a drill bit

It is necessary to purchase a tapered metal drill bit, taking into account the tasks that will be carried out by this tool, the characteristics of the steel that is going to be processed. If you decide to choose a step drill for metal, you should consider the number of steps, their diameter, pitch, height, the possibility of sharpening. In some designs of stepped models, the number of transitions reaches up to 12. These parameters determine the scope of the product, drilling speed and quality of work production.

Depending on the different sizes of holes to be drilled, select the configuration of the tool. When choosing what metal will be drilled, should be taken into account, whether it is necessary to additionally treat the surface. Depending on this, you should choose the characteristics of the tool and choose the appropriate price. It is necessary that the diameter of the product complies with the requirements of GOST.

If you expect to work with holes, defined in the metric system, it is not necessary to buy imported products with indicators in inches. You should take into account the need for frequent sharpening of step drills from a turner or yourself. The manufacturer determines the quality of the product, so you need to choose a suitable option for the ratio of price and durability of the fixture. The product should have a high resistance to wear, and the tool should be sharpened as infrequently as possible. The fixture should have a long service life.

Related articles: