Concrete drill bits are used for drilling holes and grooves for various purposes. The right choice of drilling tool will ensure high quality work and durability of the crowns.

Contents

Designation and classification

Concrete crowns are inserted into the chuck of a hammer drill or designed for a drill. They are used for drilling concrete, asphalt, granite and other hard materials. With the help of this tool, you can make holes of different diameters both in industrial and domestic scales. Concrete drilling crowns allow you to quickly and accurately perform the work, ensuring high accuracy and reliability.

Dimensions, width and dimensions of concrete drill bits depend on the purpose of use. According to the form of the product is a hollow cylinder, in the center of which the drill is installed. It plays the role of the centering element to simplify the use of the tool. Bowls are made of particularly durable metal alloys that can withstand high temperatures and prolonged impact.

The cylinder is closed at the top, where only the fastening element is located. And at the bottom there is a cutting part in the form of teeth evenly distributed around the circumference of the cylinder. The diameter of the crown determines the size of the hole.

Main crown varieties

This tool is distinguished depending on the material of manufacture of the cutting tooth. This element determines the service life of the product, how quickly and qualitatively the work will be performed. Concrete crowns come in the following types:

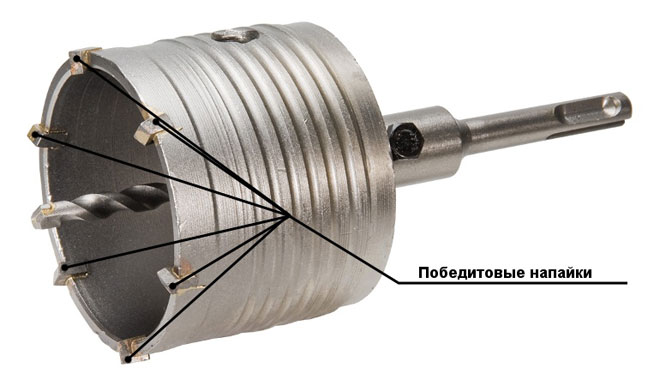

- carbide crowns made of pobedite;

- diamond;

- with carbide-tungsten coating.

Pobedite

The first type of tool is most often used for domestic tasks. It has the lowest cost, while maintaining high quality. However, this type of product cannot be used when working on reinforced concrete. Otherwise, when in contact with metal bars, there is a high probability that the teeth will break.

A large selection of sizes allows you to pick up a crown for all needs. Products range in diameter from 35 to 120 mm. The resource of cutting teeth is reduced because of the intensive impact load.

Tungsten carbide version

Tungsten carbide drill bit, unlike diamond and pobedite, lets you make holes not only in brick or concrete, but also in tile. Thanks to this you can save a lot of time, because there is no need to change several bits all the time.

Using this product requires that the power of the power tool was from 0.8 kW. The tungsten carbide tool breaks if you choose it for work on reinforced concrete. It is incompatible with reinforcing slabs.

Diamond bits

Diamond-tipped perforator bits are used when working with hard surfaces. They can easily cope not only with concrete, but also with reinforced concrete. Short-term work on metal reinforcement is also allowed. This device is a cylinder with soldered cutting segments on which the diamond abrasive is applied.

The diameter of the product for domestic work is in the range of 25-130 mm, and for industrial work can reach 600 mm. This type of tool has a high cost. The price depends on the wall thickness and the length of the cutting edge. Diamond spraying allows you to make holes in hard surfaces without impact. The advantages of this technology include the following:

- the work is not as noisy as with the percussive method of drilling;

- There is less dust in the air;

- Chips and cracks do not form on the surface of the work material;

- Low kickback of a drilling tool makes it more convenient and easier to work with;

- holes are obtained in regular shapes.

Diamond drill bits are divided into the following parameters:

- diameter;

- cylinder length;

- Type of cutting segments;

- the design of the connection to the actuator;

- method of use;

- method of operation of the drive mechanism.

Depending on the size, diamond products need protection against overheating. Drilling can be dry or wet. In the first case, no cooling system is used. This method is suitable for shallow holes in structures of any type and shape.

Wet drilling involves a continuous supply of water in an amount that is determined by the diameter of the tool. This is often specified in the instructions. If there is too much liquid, the advance into the depth will be retarded. When there is not enough water, the cutting part overheats and wears out quickly.

Features of Using Concrete Bits

You need to understand how to use a concrete drill bit to extend its life and get the desired hole shapes. Diamond and carbide drill bits with a diameter of 68 mm are in demand because they are used in the installation of electrical installations.

When carrying out the work, the following peculiarities should be taken into account:

- perform drilling only in those places where it is required by the "Rules of Electrical Installations";

- after drilling, the concrete that remains inside is removed with a chisel and hammer or a rotary hammer with a special shovel.

If carbide products are used, it is necessary to take breaks in the work to allow the tool to cool down. Otherwise it will wear out quickly. The same rule applies to diamond-powdered tools when the diameter of the product requires a wet cooling system, but it is technically impossible.

If large diameter drill bits (100 mm and larger) are used, the following must be remembered

- excessive pressure must not be applied to the cutting tool as this will cause it to overheat and break;

- Do not use wet cooling when working on reinforced concrete;

- check that the product is securely locked in the chuck of the power tool;

- all work must be carried out using personal protective equipment.

The drilling process is carried out as follows:

- if there is a drill in the center, it is applied to the middle of the future hole;

- when it is not present, the tool is applied to the surface with all teeth at once;

- it is impossible to put pressure on the tool until the entire cup is deep enough to move steadily in a given direction;

- to remove dust use special dusters or a vacuum cleaner;

- If you plan to make a deep hole, you must periodically stop and let the tool cool down;

- concrete remains inside only if the hole is made through.

The work with crowns is not particularly difficult. The main thing is to observe safety techniques and the rules of tool use.

Related articles: