No modern system of security, control, firefighting, emergency alert can not function without the use of sensors that connect it to the outside world. Sensors determine the presence of smoke, dust in the air, the movement of objects and many other changes.

The reed sensor is still used in many such systems because of its reliability.

Contents

What is a reed switch

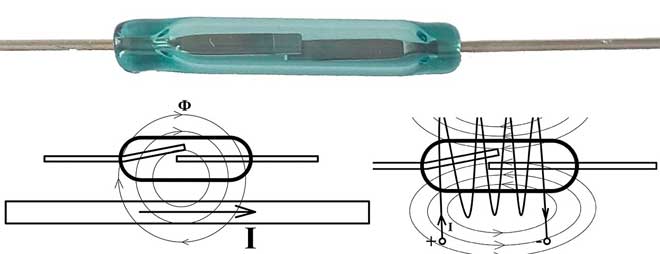

The reed switch is an electromechanical device, which closes or opens electric contacts under the influence of a magnetic field generated by an electromagnet or a permanent magnet.

The term "reed" means a hermetically sealed contact. This is due to its construction. It consists of two ferromagnetic plates, sealed in a glass capsule with two output contacts and filled with inert gas. This encapsulation minimizes environmental exposure and ensures reliable operation of the device.

The flask may contain nitrogen, dried air, or other inert gas. All gas can also be evacuated from the flask to a vacuum state. This is used to increase the level of switched voltage.

Purpose and application

Reed sensors, despite their replacement by Hall sensors, still find application in many devices and systems:

- Keyboard synthesizers and industrial equipment. The design of the sensors eliminates the possibility of a spark. Therefore, they are primarily used in explosive industrial applications where flammable vapors or dusts are present.

- Household meters.

- Automatic security and position control systems.

- Equipment operating under water or in high humidity environments.

- Telecommunications systems.

- Medical equipment.

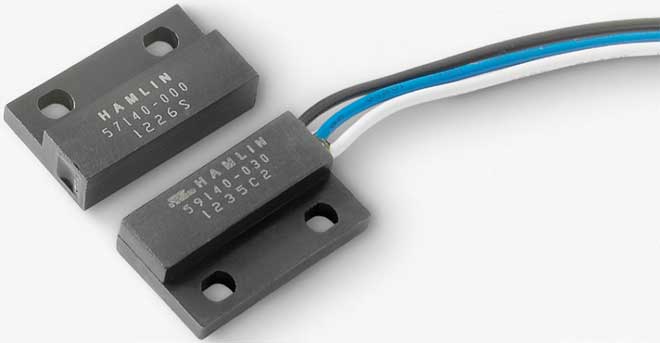

Devices consisting of a reed switch and a magnet are used in security systems. They report the opening or closing of doors.

Reed relays consisting of a contact sensor and a wire winding are also used. Such a system has some advantages: simplicity, compactness, moisture resistance, absence of moving parts.

Reed switches are also used in special areas - these are mechanisms of protection against overloads and short circuits of high-voltage and radio equipment. Also it is a high-power radar, lasers, radio transmitters and other equipment operating at voltages up to 100 kV.

Varieties of

Depending on the normal state of the contacts, devices are divided into:

- closed - the circuit opens under the influence of a magnetic field;

- switched - under the influence of the field, one contact closes, and in the absence of a field - the other;

- open - the actuation of the reed switches occurs when there is a magnetic field.

Depending on the design, the sensors are:

- gas - the glass sleeve is filled with dry air or inert gas;

- mercury - mercury is additionally applied to the contacts, which contributes to improved switching, minimizes the resistance and removes the vibration of the plates being closed.

Reed switches are subdivided according to their technical characteristics into:

- Reedlocks.

- Reed is a device that has a memory function. That is, the position of the contacts is retained after the magnetic field is turned off.

- Reed switches are relays with high-voltage insulation. Designed for use in devices with voltages from 10 to 100 kV.

- Hersikon is a relay designed to control equipment and automatics with power up to 3 kW. The design is characterized by increased switching current and the presence of arc-suppression contacts.

Due to the variety of designs reed switches continue to be used in many areas.

Operating Principle

The reed switch is similar in principle to a switch. The relay consists of a pair of conducting cores with a gap between them. They are hermetically sealed in a glass bulb with an inert medium that excludes the oxidation process.

Around the bulb there is a control winding which is powered by a direct current. When the winding is energized, it generates a magnetic field which affects the cores and causes the contacts to close with each other.

When the coil is de-energized, the magnetic flux disappears and the contacts open by springs. Reliability is ensured by the absence of friction between the contacts, which, in turn, act as a conductor, spring and magnetic wire.

A feature of the reed sensor is that no forces act on the relay springs at rest. This allows them to close the contact in a fraction of a second.

Permanent magnets can also be used. Such devices are called polarized devices.

Normally closed devices have a different principle of operation. Under the influence of electromagnetic force, a system of magnets charges the cores with the same potential, causing them to repel each other, opening the circuit.

Switched reed switches consist of three contacts. One is permanently installed and non-magnetic, the other 2 are made of a ferromagnetic alloy. When a magnetic field is applied, the pair of open contacts closes, opening the pair with a non-magnetic contact.

Connecting a Reed Switch

The documentation that comes with the sensors provides comprehensive information on how to connect the reed switch.

For the functioning and safety of the sensor, the part of the relay that generates the magnetic field is mounted on the moving part of the structure. The reed switch itself is mounted on a permanently installed element of the structure or building.

The movable part is tightly attached, affecting the magnetic field of the coil on the reed contact network and closing the electrical circuit. The system sensor informs about the correct functioning of the system. As soon as the coil located on the moving part stops acting on the sensor, the network opens and the automatics reports a violation of system integrity.

According to the method of installation, the sensors are:

- concealed mount;

- external mounting.

Depending on the physical properties of the surface on which the connection is reed, there are:

- sensors for mounting on steel structures;

- sensors mounted on magnetically passive structures.

When installing a reed switch it is necessary to remember about some peculiarities of the installation:

- It is recommended to avoid location near sources of ultrasound. It is able to have a negative effect on the parameters of the sensor.

- Do not allow the location near the source of extraneous magnetic field.

- Protect the sensor bulb from shocks and damage. Otherwise, the gas will evaporate, the contact will break, and the cores will quickly become unusable.

Reed switches cannot switch high currents due to the low capacity of the cores. Therefore, they cannot be used to switch on and off powerful electrical devices.

They are included in a low-power switching circuit to control the relay that controls the equipment.

Advantages

Reed sensors have the following advantages:

- Full tightness allows them to be used in fire-hazardous rooms and corrosive environments.

- Instant actuation allows their use in devices with high switching frequency.

- Avoiding contact bounce of mercury sensors. They are used in equipment with high demands on signal purity.

- Small size from 4 mm, simple design, low manufacturing cost.

- High functionality and versatility of the relay.

- Ability to switch low-power signals.

- Large temperature range - from -55 to + 110 ºC.

- High strength cores.

- No friction surfaces.

High versatility, reliability and price still allow reed switches to compete with direct competitors.

Disadvantages

Like all devices, reed switches also have disadvantages:

- Low sensitivity of the magnets.

- High susceptibility to external magnetic fluxes. As a consequence, you may need to use additional shields.

- Sometimes the contacts may remain in a closed position after removal of the magnetic field, from which they cannot be removed.

- The capsule is made of thin glass and is easily destroyed by falls and shocks.

- When a low frequency voltage is applied, the contacts open and close the circuit spontaneously.

- When high currents are applied, the core contacts can open spontaneously.

For these reasons, a number of restrictive measures specified in the accompanying documentation must be observed when using the relay.

Related articles: