Hydrogen - almost the perfect fuel for our planet. The only problem is that it occurs on the planet only in combination with other substances. Pure hydrogen on the Earth is only 0.00005%. In this connection, the question of constructing hydrogen generators is very relevant. We should not forget that hydrogen is an endless source of energy, practically under our feet.

Contents

Design and operation of hydrogen generator

How it works

The classic apparatus for generating hydrogen includes a tube of small diameter, often - with a circular cross-section. Underneath it are special cells with an electrolyte. The aluminum particles themselves are located in the lower vessel. The electrolyte in this case is only of the alkaline type. Above the feed pump there is a tank where the condensate is collected. In some models 2 pumps are used. The temperature is controlled directly in the cells.

The generator receives gas from water. Its quality directly affects the amount of impurities in the finished product. So, if water with a high concentration of foreign ions gets into the generator, it first has to go through a deionization filter.

This is how the process of gas production takes place:

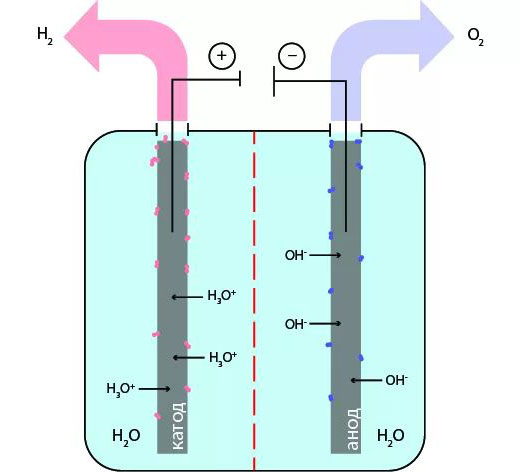

- The distillate is split into oxygen (O) and hydrogen (H) in an electrolysis process.

- The O2 goes into the feed tank and then escapes to the atmosphere as a byproduct.

- The H2 is delivered to the separator, separated from the water, which then flows back into the feed tank.

- The hydrogen is re-passed through a separating membrane, which extracts the remaining oxygen and then enters the chromatographic equipment.

Electrolysis method

As mentioned above, there are almost no energy sources in the world as inexhaustible as hydrogen. We should not forget that the world's oceans are two-thirds composed of this element, and H2, together with helium, occupies the largest volume in the entire universe. But to get pure hydrogen, you need to split the water into particles, and to do this is not very easy.

Scientists, after years of tricks, have invented a method of electrolysis.. This method is based on placing two metal plates in water at a close distance from each other, which are connected to a large voltage source. Power is then applied - and a large electric potential actually breaks the water molecule into components, resulting in the release of 2 hydrogen atoms (HH) and 1 oxygen atom (O).

This gas (HHO) was named after the Australian scientist Yull Brown, who patented the creation of the electrolyzer in 1974.

Stanley Meyer's fuel cell

U.S. scientist Stanley Meyer invented a facility that used currents of a certain frequency rather than a strong electric potential. A water molecule swings in time with changing electric impulses and enters the resonance. Gradually it gains power, which is enough to split the molecule into components. This effect requires tens of times less current than the functioning of a standard electrolysis unit.

IMPORTANT! Meyer paid with his life for his invention. Rumor has it that he was killed at the behest of the tycoons, because his invention could have killed the oil business at its roots. Nevertheless, some of the scientist's work has survived, so his contemporaries have the opportunity to try to make such apparatuses.

Advantages of Brown's gas as an energy source

- Water, from which HHO is derived, is present on our planet in enormous quantities. Accordingly, the sources of hydrogen are almost inexhaustible.

- The combustion of Brown's gas produces water vapor. It can be condensed back into a liquid and used again as a raw material.

- Combustion of HHO does not release any harmful substances into the atmosphere and produces no by-products other than water. It can be said that Brown's gas is the most environmentally friendly fuel in the world.

- When using a hydrogen generator, water vapor is released. Its quantity is enough to maintain a comfortable humidity in the room for a long time.

IMPORTANT! Hydrogen can also be obtained by cracking oil refineries (the gas is released as a by-product). This method is cheaper than the electrolysis method, but it may be difficult to transport the gas. In addition, the gas produced by electrolysis is much cleaner than the gas produced by cracking.

Use of hydrogen generator

H2 is a modern energy carrier that is actively used in many industrial applications. To name but a few:

- Hydrogen chloride (HC)l generation;

- Production of propellant for rocket launchers;

- Production of ammonia;

- metal processing and cutting;

- development of fertilizers for cottage plots;

- synthesis of nitric acid;

- creation of methyl alcohol;

- food industry;

- hydrochloric acid production;

- creation of underfloor heating systems.

In addition, HHO has become very useful in everyday life, although with reservations. First of all, it is used for autonomous heating systems. In addition, Brown's gas is added to gasoline in an attempt to cheat the engine and save on fuel.

In both cases, there are peculiarities. So, when organizing home heating, you need to take into account that the combustion temperature of HHO is an order of magnitude higher than that of methane. Because of this, it is necessary to purchase a special, not cheap, boiler with a heat-resistant nozzle. Otherwise, the owner and his home will be in considerable danger.

As for using a generator in a car, sometimes the system can work - if it is designed correctly. But it's almost impossible to find the ideal parameters or power gain factor. In addition, it is not quite clear how much the life of the engine will be reduced, and certainly replacing it will cost a pretty penny.

What is needed to make a fuel cell at home

Creating a hydrogen unit at home is not an easy task. You need to arm yourself with not only a number of tools, but also the appropriate knowledge and schematics.

Designing a hydrogen generator: schematics and drawings

The device consists of a reactor with installed electrodes, a PWM generator for power, a water gate, wires and hoses connecting the structure. To date, there are several known electrolyzer circuits where plates or tubes are used as electrodes.

Dry electrolysis units are also popular. Unlike the classic version, in this unit not the plates are placed in a tank with liquid, and the water itself is directed into the slot between the flat electrodes.

Selection of materials for building a hydrogen generator

To make a generator at home you do not need any special and unusual tools. Here is what you will need to prepare:

- A hacksaw for working with metal products;

- a drill and drills for it;

- a set of wrenches;

- a flathead screwdriver and a slotted screwdriver;

- angle grinder ("grinder") with a wheel for cutting metal;

- multimeter and flow meter;

- ruler;

- marker.

Hydrogen generator with your own hands: instructions

The process starts with the creation of a hydrogen production cell. In terms of dimensions, it should be slightly less than the internal parameters of the length and width of the generator body. It is 2/3 the height of the main body. The cell is made of textolite or Plexiglas (wall thickness 5-7 mm). For this purpose, 5 plates are cut to size, of which a rectangle is glued, and its lower part is not covered with anything.

Using a grinder, electrode plates are cut out of a sheet of stainless steel. Their size should be smaller than the side walls of 10 - 20 mm.

IMPORTANT! To get a sufficient amount of HHO, the stainless steel should be treated with emery on both sides.

In each plate it is required to drill 2 holes: for water supply to the space between the electrodes and for drainage of Brown's gas.

The water inlet and gas outlet connections are inserted into the organite walls. The joints where they have been connected are carefully treated with sealant. One of the transparent casing pieces is fitted with studs, and then proceed to laying the electrodes.

IMPORTANT! The flatness of the plate electrodes must be flat, otherwise the elements may cause a short circuit.

The plates are detached from the sides of the reactor using sealing rings, which can be made from silicone, paronite or other material. After placing the last plate, mount the sealing ring, and then close the generator with the second organite wall. The resulting construction is fastened using washers and nuts.

The generator is connected to the water tank and bubbler using polyethylene hoses. The contact pads of the electrodes are connected to each other, and then the power supply is connected to them. The cell is supplied with voltage from a PWM generator.

Hydrogen in home conditions: is there a benefit

Let's note right away: using a hydrogen generator for home heating is not profitable. You will spend more electricity to emit pure H2 than you will get after burning it. So, for 1 kW of heat it takes 2 kW of electricity, i.e., there is no benefit. It is easier to install at home any of electric boilers..

To replace 1 liter of gasoline for the car, it would require 4766 liters of pure hydrogen or 7150 liters of rattlesnake gas, 1/3 of which is oxygen. So far, even the best minds in the world have not developed a unit capable of producing such a capacity.

Maintenance of hydrogen generators

The equipment is subject to careful maintenance. Experts advise adhering to the following tips:

- Do not improve or modify the generator yourself, even with a professional engineering drawing;

- it is recommended to install special temperature sensors on the equipment inside the heat exchanger, which will allow you to monitor the process of water overheating;

- a shutoff valve can be installed in the burner and connected to the temperature sensor. This will allow the device to cool normally.

Homemade generator allows you to get hydrogen, but it is used mainly for experiments and gas welding. To heat a considerable structure, the efficiency of the device is simply not enough. And you should not forget about the low efficiency of the device, as well as the hassle and expense of assembling it.

Related articles: