KG (cable flexible) - a power conductor, which has a wide range of applications. It is mainly used as an electrical wiring or welding cable. The conductor is designed for a voltage of 380 V and 660 V. The wire can have several strands - from one to four. Four-core cable includes 1 ground loop and 3 phases.

Field of application

KG cables are used to connect mobile machinery to the power grid. They are suitable for indoor and outdoor use. It is not allowed to lay underground, as well as for stationary connection of installations. The wire insulation is not designed to withstand mechanical stresses. It can be damaged even by pressure from hard soils. However, laying the cable in pipes is permitted.

If safety precautions are observed, the conductor can be laid outdoors. It is capable of withstanding sub-zero temperatures.

KG wire is often used to connect cranes, submersible pumps and welding machines.

Wire deciphering

Deciphering of cable KG:

- The letters "KG" indicate that the cable is flexible.

- The prefix "H" - non-combustible, with an additional layer of protection.

- "T" - suitable for use in tropical conditions. The minimum ambient temperature must not fall below -10 ºC. In our region such cable is practically not found.

- Prefix "ХЛ" means that a conductor can be used even at -60 ºС.

Technical Characteristics

The flexible KG cable has some peculiarities that make it universal for indoor and outdoor usage:

- Can be used at 100% moisture conditions;

- Power cable is flexible, permissible bending radius is not less than 8 cable diameters KG;

- Recommended for use on devices with high levels of vibration.

However, there are some limitations. For example, to connect portable devices, consider the following points:

- the maximum voltage in the mains - 660 V;

- when connected to AC mains, the maximum frequency of vibration is 400 Hz;

- the power consumption must not exceed 630 A;

- when connecting the power KG conductor to the electric network with direct current, the maximum voltage is 1000 V;

- cable operation should be carried out at ambient temperature -50...+70 ºС;

- laying without heating should be carried out at a temperature not lower than -15 ºС;

- core temperature should not exceed +75 ºС during long-term works.

If the above parameters are observed, the service life of the cable will be 4 years.

Previously, it was already noted that the copper power wire KG can consist of four conductors. However, there is another parameter that is responsible for the characteristics of KG cable in relation to the load capacity - the cross section of the core. The dimensions of the cross sections:

- In a single-core conductor, the cross-section can be from 2.5 to 50 mm²;

- two-core and three-core cable - cross-sectional area from 1.0 to 150 mm²;

- four-core - cross-section from 1.0 to 95 mm²;

- five-core - from 1.0 to 25 mm².

In this case, the core of the ground loop always has a value below the core of the phase. For example, the cable KG 3×6+1×4. Here it is specified that the 3 cores of the phase has a cross-sectional diameter of 6 mm ², and the ground - 4 mm ². The exceptions are sections 1.0 and 1.5. In these cables, the grounding has the same diameter as the phase.

Equally important are the temperature ratings, which directly affect the service life of the conductor. Most cables of KG series are used at ambient temperatures of -40...+50 ºС. Some wires can be used under other temperature conditions. They are marked with additional marking "ХЛ" or "Т".

When checking the wire resistance, 1 km of KG welding cable, air temperature +20 ºС, oscillation frequency 50 Hz and the power of 2,5 kW are taken as a basis. In this case the resistance should be 50 mOhm. When testing single-core cable, it is placed in water. The temperature value +75 ºC indicates that the cable is suitable. A higher value indicates a problem. It can be wear of the insulation layer or breakage of some wires.

Important: The length of the product depends on the used cross-section:

- wire with a cross-section from 1 to 35 mm² can have a length of not more than 150 m;

- 35-120 mm² - 125 m;

- 150 mm² - 100 m.

Modifications

The KG series consists of several modifications, such as the KGVV wire. Its peculiarity lies in the fact that it does not use rubber insulation, but polyvinyl chloride. This approach makes it possible to increase the service life by up to 25 years. This kind of conductor is used for large machinery and apparatus that can operate from both DC and AC voltages. Examples include cranes, mining excavators and other mobile machinery.

Polyvinylchloride sheath makes it possible to operate the conductor in a wide temperature range: -50...+50 ºC. It means that the wire is not limited by any parameters regarding climatic conditions.

KGH cable is another popular modification of KG series. Its main difference lies in its higher oil resistance and incombustibility. According to the accepted standards, the abbreviation is deciphered as follows:

- "KG" - cable products have flexible properties;

- "H" - the use of non-combustible rubber as an insulation layer.

The cable design consists of a number of basic elements:

- copper core, corresponding to the 5th class of flexibility;

- Separation layer, which prevents sticking to the insulation;

- rubber insulation with color marking;

- sheath of oil-resistant non-flammable rubber.

KG XL cable is equipped with copper cores in rubber insulation. This conductor is designed to connect mobile large machinery to the power grid. Nominal voltage at direct current is 1000 V, at alternating current - 600 V. The pulse frequency is 400 Hz. It is allowed to bend a wire not less than 8 diameters. Maximum core heating temperature is +75ºC. The letter "H" is added to the marking in the presence of zero conductor.

Conductor construction:

- Multi-wire copper conductor of grade 4 or higher.

- Separation layer.

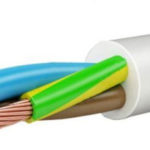

- Core insulation. May be solid color or with longitudinal stripes. Grounding is green-yellow and grounding is blue. If grounding is not present, blue can be used for any conductor except the grounding circuit. The manufacturer can coordinate with the customer the types of coloring of cores.

- Hose rubber sheath capable of withstanding low temperatures.

Another modification is RKGM. The abbreviation stands for the following:

- "R" - rubber;

- "K" - use of silicone insulating material;

- "G" - bare wire;

- "M" - copper cross-section.

The diameter of the section can vary from 0.75 to 120 mm². High flexibility: the turning radius should not be less than two diameters. Connects to AC networks with a frequency of 40 Hz and a voltage of 660 V.

These characteristics allow to use the conductor for connection of various devices and tools. It is allowed to be laid in an open area, because the insulation is resistant to solar ultraviolet light and moisture. At the same time, you should remember the lack of protection against corrosive substances and oils.

Related articles: