The easiest and most accessible wire used in everyday life - this wire PVS. It can be easily found in every apartment. It is used as a flexible connection of household appliances with a plug, or socket. Repeated bending and moving does not affect its performance and reliability, does not violate the qualities of the insulation, and the strength characteristics ensure the integrity under permanent, but small stretching, or compression. Among the useful properties of PVS is that it is soft to the touch and has a familiar aesthetic appearance.

It is also used for installation of fixed wiring, especially in cases where you want to temporarily connect the consumer with the power source, which are apart by a few meters. Such a conductor, if necessary, can be safely suspended above the ground, and between the points of attachment leave wide spans. And if you need to quickly throw the wire along a complex and winding path, it is easier to use just such a soft and elastic electric wire.

Contents

Description of properties and deciphering of PVS

PVS wires are not only used to connect household appliances to 220 V. Certain varieties can be used to transmit voltages up to 660 V. Service life of the wire can also range from 2 to 10 years. It all depends on operating conditions and the quality of the insulation material. The abbreviation of the name of the wire PVS stands for:

- "P" - conductor.

- "B" - polyvinyl chloride insulation.

- "C" - "mains".

Also, this abbreviation indicates the way of packing conductive cores in a single cylindrical package of PVC.

One of the purposes of PVS wire is the ability to operate outdoors. Therefore, the permissible operating temperature range for it - from -30 ° frost to +45 ° heat. Permissible temperature of heating wire PVS - +80 °, after which its sheath begins to melt and break down, which can lead to short circuits. PVS cable is considered a flexible conductor, but it has a bending strength limit - up to 50,000 in one section.

Design Features

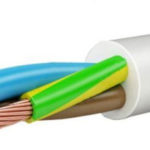

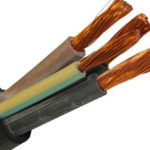

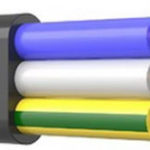

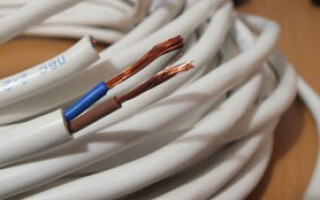

PVS cable consists of several components:

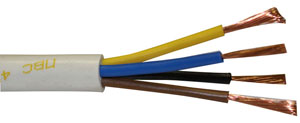

- The number of conductors - from 2, to 5. They are made of thin copper wire, woven into tight cores.

- PVC insulation. It is covered each core, and all cores are in a common PVC insulation package, which has a circular cross-section.

- For the designation of phase conductors, colored insulation is used in colors such as brown, gray, yellow, red and black.

- The neutral conductor jacket is always blue.

- If a grounding element is present, its coating is either green or yellow-green.

The cross-sectional area of a PVS wire varies from 0.4 cm² to 0.5 mm². The color of the outer sheath of PVS wire is usually white. But there are two-color versions - with longitudinal stripes of contrasting shades. The outer insulation is soft, well cut with a knife and easy to remove during installation operations. Depending on the cross section and the number of conductors weight of 1 km of the product can be from 50 to 250 kg.

Marking

Existing pvc brands have the following standards (GOST 7399-97):

- Tin-plated copper as phase wires - PVSl;

- Antiseptic additives as part of the insulation material - PVAt;

- Flat cross-section of the outer insulating layer - "SHV";

- Reinforced outer protective jacket - "B";

- Insulation material has increased resistance to combustion - "PS".

In addition to the letter code, the Pvs cable marking contains numbers, which are deciphered in the following order:

- The number of conductors is indicated by the first digit.

- After the "x" symbol follows the cross-sectional area of 1 conductor in millimeters:

| Two-core | Three-core | Four-core | Five-core |

| 2х2,5 | 3х2,5 | 4х2,5 | 5х2,5 |

| 2х1,5 | 3х1,5 | 4х1,5 | 5х1,5 |

| 2х1 | 3х1 | 4х1 | 5х1 |

| 2х0,75 | 3х0,75 | 4х0,75 | 5,0,75 |

The same figures indicate the weight of 1 km of the product:

| 0.75 mm² | 0,1 mm² | 1,5 mm² | 2,5 mm² | |

| Two-core | 55,8 kg | 66,1 kg | 79,8 kg | 102 kg |

| Three-core | 63,7 kg | 76,5 kg | 96,5 kg | 118,4 kg |

| Four-core | 85,15 kg | 107 kg | 134,5 kg | 170,6 kg |

| Five-core | 133 kg | 166,7 kg | 203,8 kg | 257,6 kg |

Characteristics

PVS wires have the following technical characteristics:

- Depending on the cross section of the phase elements, the product can withstand currents up to 2 kW;

- When stretching, the breakage occurs after the length increases by half;

- The optimum operating temperature ranges from plus 40 ˚C to minus 25 ˚C;

- Freeze resistant PVS brands are marked with a special symbol "Y". It indicates the lower temperature threshold to - 40 ˚C;

- The warranty period is usually 2 years;

- When laid alone, the shell of the product does not support combustion. In the case of fire in prolonged contact with an open flame, it has the property of self-extinguishing;

- PVS-T has a coating that has a number of special properties, increasing the service life in hot and humid climates;

- It is allowed to use at high air humidity (up to 98%);

- The radius of safe bend is not less than 4 cm;

- Service life is 5000 hours when used as a temporary wiring or carrying element. When used as fixed and permanent wiring - 12000 hours.

PVS cable from different manufacturers may have different technical characteristics, even if the markings are the same. Differences may concern such parameters as:

- The thickness of the insulation layer;

- Cross-section of conductors;

- The number of copper wires in the stranding.

An exact description of the properties of a particular PVS can be found in the supplier's documentation.

Scope of application and operating features

PVS wires have the following areas of application:

- In the home;

- At work;

- As general wiring in buildings and structures.

Examples of domestic uses include the following:

- Carriers;

- Connections of household appliances to the mains;

- As wiring in the installation of outlets, switches, stationary household lighting devices.

Advantages:

- Beneficial resistance parameters.

- Resistance to mechanical deformations.

- Minimal expansion under heat.

- Preservation of working parameters at sudden surges in voltage in the network.

The advantages of flexible wire PVS allow its use in the installation of city lighting, wiring in apartment buildings and for connecting industrial electrical installations.

Related articles: