Various types of wires and cables are used for power supply of various purposes, residential, administrative buildings and industrial facilities. One of the most popular is a cable brand VVG, he has many parameters meets the many requirements under various operating conditions.

Contents

Field of application

VVG cable is used for laying inside residential apartments and public buildings. Suitable for installation of lighting lines, socket groups and power supply of individual household appliances with high power consumption, such as electric stoves, heating boilers, split systems and air conditioners and equipment with powerful electric motors.

VVG is designed for transmission and distribution of electricity at voltages of 0.66, 1, 3 and 6 kV frequency of 50 Hz, the cross section of the wires depends on the magnitude of the current consumption. Laying is permitted:

- Outdoors, provided it is protected from UV rays and there is no danger of mechanical damage;

- Through the air on cable ties;

- On the walls of structures;

- On the surface of the ground;

- In dry rooms and with high humidity;

- In tunnels on cable sheeting (cable trays of ladder type);

- In cable shafts;

- In rooms with high fire danger.

Underground it is recommended that it be laid only in metal, asbestos or plastic pipes.

Deciphering of abbreviations and modifications

The abbreviation, which is applied to the outer surface of the cable insulation jacket, denotes its design features and technical characteristics. The sequence of letters and numbers carries certain information. The first capital letters VVG denote the following:

- B - the material from which the insulation of the conductive cores under the outer sheath is made, in this case it is polyvinyl chloride. The letter "B" comes from the name of the main component material of the insulation layer of vinyl;

- B - the material of the outer sheath, the main composition of which, is also vinyl. Such insulation is commonly referred to as PVC, it is a thermoplastic. 43% of its composition is a petrochemical product of ethylene and 57% of bound chlorine. The composition of plastic insulation may vary, some models use PVC sheathing with impurities that block the spread of fire.

- D - indicates that the total sheath of conductive wires does not have an armored layer, such cable is called naked, having no protection against hard mechanical influences.

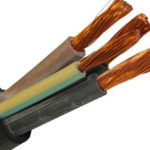

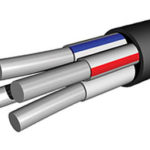

All models have copper wires with a rigid monolithic or flexible multicore structure.

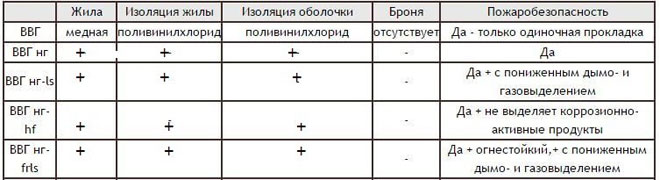

There are a number of modifications of plastic insulation:

- VVGpng - in this variant, the added letter designation "png" indicates that it is allowed to be laid as part of a group of cables of other brands. Its outer sheath does not propagate combustion. (ng - flat non-combustible)

- VVGng-ls means that the composition of the plastic insulation with impurities, which in combustion reduce the release of toxic gases and smoke;

- VVGng-hf In case of strong environmental fire and high temperature the insulating layer burning out does not emit corrosive gases;

- VVGng-fr indicates the presence of mica tape in the insulation layer, which creates a thermal barrier between the environment and conductive cores.

If there are no such designations, they propagate burning of the insulation, it is the usual VVG.

Cable marking VVG in the digital abbreviation indicates the number, and the cross-section of conductive conductors.

VVG png 3x2.5+1 power cable in this variant of VVG, the decoding of the marking shows:

- png - flat, non-flammable;

- 3 - number of current-conducting conductors;

- 2.5 - cross-sectional area of the wires;

- +1 - additional ground wire in the cable.

For laying under the plaster most convenient to use wire VVG n - flat design, it is compactly stacked in the strokes and easily plastered without protruding on the surface.

Technical Specifications

The choice of cable depends on operating conditions, the designated purpose of the object, power of electric installation which it supplies, so you need to consider many technical specifications wire VVG:

- One of the most important parameters is the cross-section of the current-conducting conductors of the cable, manufacturers supply to trading networks the most popular brands with a cross-section of 1.5 mm2... 35 mm2. Cables with larger cross-section up to 240 mm2 . Cables with larger cross-section up to 240 mm are ordered individually from manufacturers.

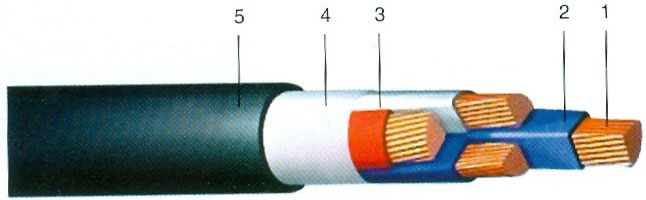

Example of multicore cables with triangular (sector) shape of cross-section.

VVG copper cable has conducting cores with circular cross-section, for high voltage versions the shape of conductor cross-section is triangular (sector) shape.

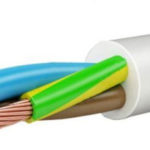

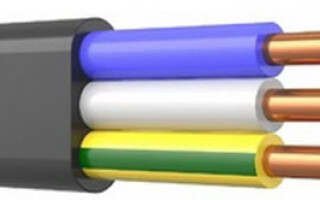

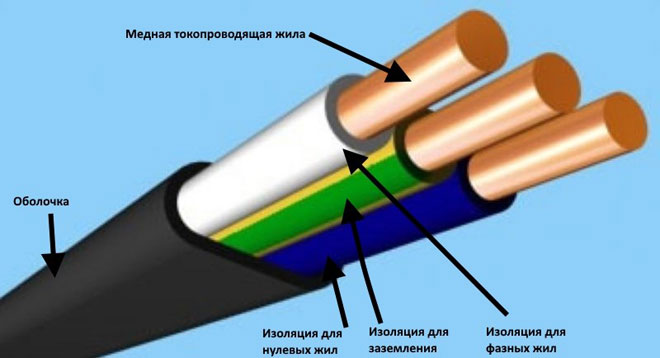

- Not unimportant parameter is the number of conductors in the cable, single-phase networks with 3-4 wires or three-phase wires with 4-5 wires are used to power equipment. Three wires are used as phases, one neutral blue and yellow-green for grounding. The extra ground conductor is made one step smaller than the phase and neutral conductors.

Table 1: Sectional Ratio of Phase and Grounding Conductors in a VVG Cable.

| Primary conductors, mm2 | 1,5 | 2,5 | 4 | 6 | 10 | 16 | 25 | 35 | 50 |

| neutral core, mm2 | 1,5 | 1,5 | 2,5 | 4 | 6 | 10 | 16 | 16 | 25 |

| Earthing wire, mm2 | 1,0 | 1,5 | 2,5 | 2,5 | 4 | 6 | 10 | 16 | 16 |

- On the cross section of the cable and the conditions of its installation depends on continuous allowable current load.

Table 2. Current carrying capacities of cables with copper conductors with PVC insulation and halogen free polymer compositions.

- Laying is not recommended at temperatures below 15 ° C without additional heating. At low temperatures, the insulation jacket may break during uncoiling of the coil;

- Operation is allowed at ambient temperature in the range of -50 ... +50 °С;

- Operating temperature of current-carrying cores under load is 70 °С in emergency mode for a short time allowed 90 °С;

- Cable bending during laying is limited by 10 radii with rigid monolithic copper conductor. Flexible multi-core cables are allowed to bend at 7.5 cable radii.

- Weight of the cable VVG ng ls, VVG ng - hf or other modifications depends on the cross-section, the number of conductors, insulation thickness, measured in kg/m.

- Most manufacturers of VVG cable specify a service life of at least 15 years while observing the rules of operation.

This average technical characteristics, they depend not only on the modification, but also from manufacturers, for an accurate description, properties must be guided by the passport data. Each manufacturer to his product attached description and technical characteristics.

Design features of different modifications of VVG

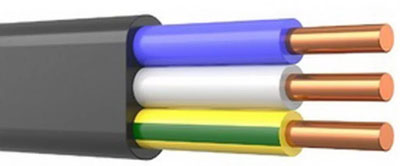

The copper conductors are double PVC, insulating the conductive strands individually and generally sheathed. Some heat-resistant models have a mica gasket between the main sheath and the wires.

The conductors can be single-wire, rigid or flexible multi-wire, in some models the wires are arranged in a single row and compressed with an outer insulating jacket. Such cables are called flat cables, the abbreviation is indicated by the letter "p".

Good characteristics, reliability and ease of installation work make wires brand VVG in demand among consumers. Therefore, many companies produce them. Years of operation show the most reliable manufacturers:

- Podolskkabel;

- Pskovkabel;

- Sevkabel;

- Moskabel.

Therefore, when buying, try to ask sellers for products of these companies.

Related articles: