Self-Containing Insulated Wire (SCIW) is one of the most popular cables for overhead transmission of electrical energy, so it is often necessary to use various connections when connecting consumers, repairing cable lines or extending them. This article will describe various ways of connecting this conductor to each other, as well as to conductors of other than CIP construction.

Contents

Diagram of connection of LV-ABC wire

An experienced electrician has an idea of how to connect self-supporting cables, but to the average person this question seems rather complicated. In fact, the connection of self-supporting cables is not an easy task, but it is doable even if you have no experience. The most important thing is to observe all safety precautions and protection against electric shock.

So, to begin with, it's worthwhile to understand what kind of construction wires can be connected with CIP-cables and what are the fundamental differences in such work.

The main problems usually encountered when working with self-supporting insulated cables are their connection to each other, as well as Connection to an aluminum or copper cable. The connection itself can be made both on the pole and in the span between the pylons. Let's analyze each type and method separately.

What does it mean to connect an LV-ABC cable in the span

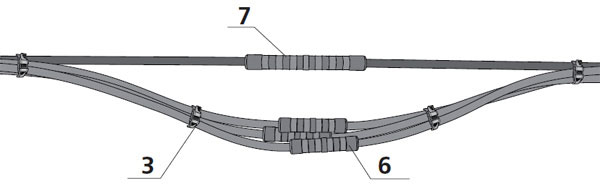

The need for over span connection may arise in various situations, such as line breakage. Another name for such a connection is the intermediate connection. The peculiarity of construction of an electric LV-ABC cable is its self-supporting capacity, which does not require a separate supporting cable. Therefore, the peculiarity of the connection in the span is that an increased load-bearing capacity and reliability of the connection is required.

For intermediate connections, special clamps are used, which should have a mechanical strength of at least 90% of the breaking force of the wire and be airtight. The sleeve should be selected according to the cross-section of the cable and the conductor design, which is specified in the marking of each sleeve. Typically, MJPT or GSI-F sleeves are used in this type of work (for phase conductors) and GSI-Nfor neutral).

The procedure for this connection is as follows:

- Both ends of the connected LV-ABC conductors are stripped of their insulation.

- The conductors are inserted into the clamping sleeve on each side, and the sleeve must be inserted as far as it will go and not have any uninsulated parts peeping out of the sleeve.

- The hydraulic tool is used to crimp the thermowell and it is important to select the correct crimping die.

- If contact grease has come out of the sleeve, it must be removed with a dry cloth.

Extending an LV-ABC cable with each other

To extend an LV-ABC cable you need to know its brand and cross section. Such work is also done using sleeves, as using other methods is not recommended when connecting or extending this type of cable. Cable extension can be carried out with a cable of similar cross-section or with a different one - the use of special clamps allows to do it.

MJPT or GSI-F clamps are also used for this purpose (for phase conductors) and GSI-N (for neutral carrier). The technology to perform such work is similar to that described above.

Connection with an aluminum wire

Connecting dissimilar conductors directly is categorically not recommended, as it contributes to rapid oxidation of the contact and rapid failure of the connection, which can cause a lack of electricity or fire. The same applies to the connection of CIP cable with aluminum taps. Special clamps are used for such connections.

The preferred clamp for connecting an aluminum wire to an LV-ABC cable is the tap clamp, which electricians call "nuts. The choice of this method is due to the fact that aluminum wires are more sensitive to notches from piercing clamps.

The procedure for making such a connection is as follows:

- Both cables are carefully stripped of their insulation at the connection point;

- Bolt connections on the clamp are unscrewed, both conductors are inserted into special grooves;

- The bolts are tightened securely and the conductors are secured in the clamp;

- "Walnut" is closed with a special plastic case;

- For greater reliability, the place of connection is additionally insulated.

Connection with copper cable

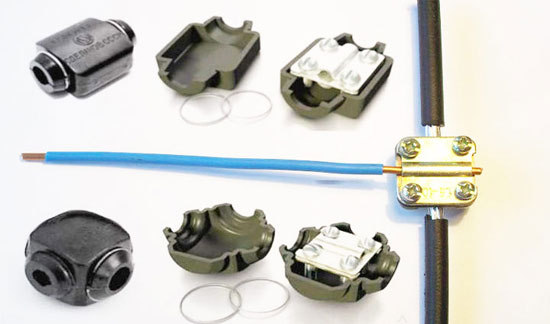

With copper conductor-branch (e.g, VVGcable) there are several connection options. For example, you can connect such wires with the same "nuts" or use piercing clips, and it is important to understand that the direct connection of the CIP cable and the copper conductor is also prohibited.

Consider the connection with piercing clips as the most preferable, because there is less damage to the insulation of the LV-ABC wire. This method is also sealed and protects against external negative environmental factors. Moreover, connection with such clamps can be made on live lines. The only disadvantage of such a clamp is that a secondary connection is not possible because of the tearing of the bolt head.

Such a connection is made as follows:

- The conductors are inserted into the holes of the piercing clamp, and it is not necessary to remove the insulation;

- The clamp is tightened with a bolted connection: the studs pierce the insulation and securely fix both conductors, creating a perfect contact.

Types of piercing clamps:

Р4 - Designed for connection of different subscribers or street lighting, with contact plates made of aluminum or tinned copper;

P616R - is used for connection of residential house lead-in cables, made of tinned copper;

Р645 - is used to connect taps made of copper or aluminum.

The conclusion from this article can be made as follows: the direct connection of the cable to each other and its increase in the span or on the tower is carried out with special crimp sleeves, and the branches are performed by tapping or piercing clips.

Related articles: