Connection of wires affects the safety and reliability of electrical wiring. Performed in different ways, with the use of connecting devices, devices depending on the characteristics of the wires.

Contents

- 1 Why use a junction box?

- 2 Ways to connect conductors

- 2.1 Using terminal blocks

- 2.2 Spring clamps

- 2.3 Installing protective equipment caps

- 2.4 Crimping with special sleeves

- 2.5 Soldering or welding

- 2.6 Twisting and insulating

- 2.7 Nut clamping

- 2.8 Using a bolt

- 2.9 Connect multiple wires

- 2.10 Connecting wires with different cross sections

- 2.11 Connecting stranded and solid products

Why use a junction box?

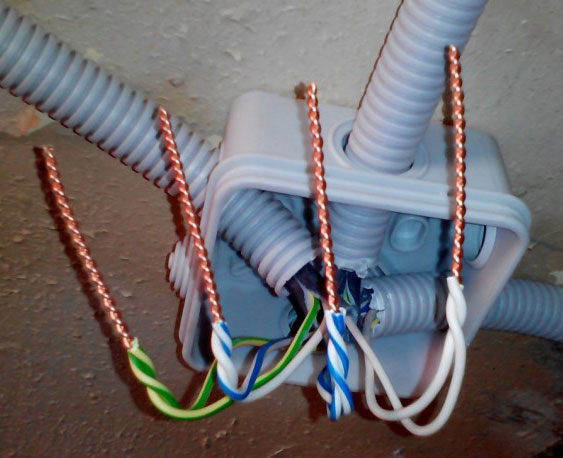

Junction (otherwise known as unplugging, splitting) box - a type of wiring box in which the switching of wires, electrical connections. It can be round, rectangular, square in shape, plastic, steel, fiberglass, aluminum material.

The device is a container, the purpose of which, with any method of connecting the wires in the junction box, is to hide the branching of the electrical network. In addition, it allows you to effectively redistribute the load on the networks, preventing short circuits in them.

There are many ways to connect wires in a junction box. The simplest - twisting - used to be a priority. Today it is considered dangerous, unreliable. It has been replaced by special connecting devices, devices designed for the different characteristics of the cables to be connected.

Ways to connect wires

Properly connect the wires to each other, it means to ensure the reliability and safety of the electrical network. The types of connection of wires are numerous. You can use the long used - twisting, soldering, bolted connection. It is easier and faster to perform the work, using a cable connector - a special device that allows you to reliably connect cables of different diameters, single- and multi-stranded, from different materials,

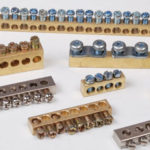

Using terminal blocks

Terminal blocks are a type of wiring product. They are called terminal blocks, terminals, terminal blocks, terminal blocks, KBs, terminal clamps, terminal connectors. They contain 2 or more metal contacts. The latter have nodes in which cables are fastened, and are placed inside a dielectric housing, often hermetically sealed (filled with gel).

There are many types of terminal connectors. They are distinguished by:

- by the method of installation: screw, split, push-pull, barrier, pass-through;

- single-, double- and multi-row;

- for one-two-, two-, three-row and multilayered cables;

- angled and straight;

- for single-core and stranded, flexible conductors;

- by wire clamping method: screw, spring, knife, end.

The cable connector is inexpensive. Contains a clamping cage enclosed in a plastic housing. The clamp is made of phosphor bronze, stainless steel; the body is made of polyamide; the screws are made of brass, nickel-plated or galvanized steel.

Electrical wires are connected by the device in the following order:

- The ends of the cables are stripped of insulation;

- 1 conductor is inserted into the clamping cage, fixed, depending on the type of terminal device with a screw, spring, knife;

- To form a network, 1 or more conductors are inserted into it and clamped in the same way.

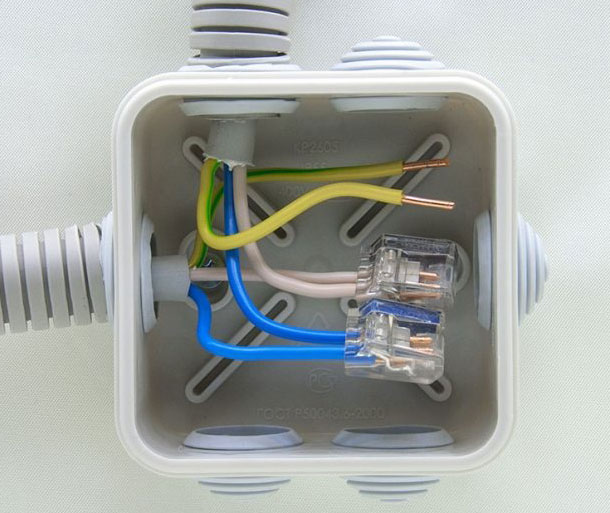

Spring-loaded terminals

These are terminal blocks in which the cables are secured by a plate (busbar) under the force of a spring. Types of connection of electrical wires using such devices:

- fast, saving up to 80% of the time of the electrician-installer;

- do not require a screwdriver - the conductor is fixed by the terminal mechanism after insertion;

- provide a constant contact force on the conductor, do not deform it;

- allow to connect cables of different material and cross-section.

How to connect two wires:

- remove the insulation from the conductors (1 cm);

- lift the lever on the clip body;

- Insert the end of the cable into the connector;

- lower the lever in place.

There are terminal variants without levers. In these, the wire is automatically clamped after being inserted into the slot of the connector. Most of them come filled with a special gel inside, which makes the devices airtight connectors that provide the highest level of protection.

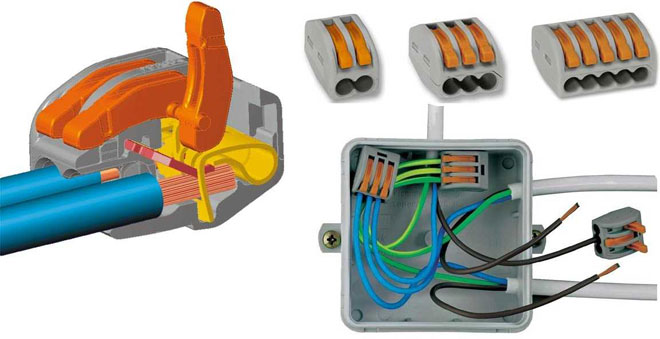

Installation of PPE Caps

This type of cable connector is a cone-shaped cap made of non-flammable plastic. It may contain a tapered metal spring or a sleeve with a coarse thread. Used for a better twist connection, protects it by providing reliable insulation.

Caps with a spring are screwed on the made beforehand stranding. The spring, due to the pressure of the conductors, expands, providing additional compression of the connection place.

Threaded caps can be screwed onto cable ends without a pre-twist device. By making 2-3 turns, a secure twist connection is obtained inside the PPE cap.

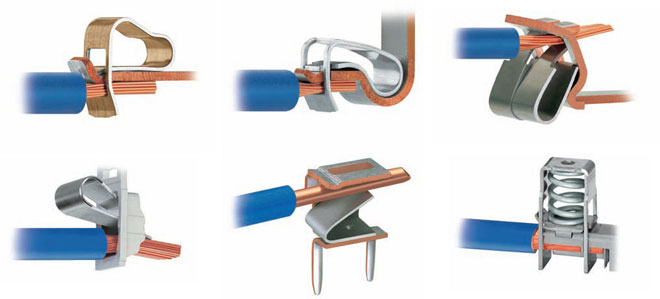

Crimping with special sleeves

Connector electrical wires are tubular elements - sleeves. Suitable for networks with medium and high currents. Provides a good electrical contact, the strength of the connection - the highest among the methods used. In the disadvantages of the method - the conductor later can not be disconnected.

Make a connection of wires without soldering in this order:

- Remove the insulation from the cables on the ends. Use a knife, a special tool.

- The ends are inserted inside a tube of similar material. Placement should be tight - reseal, if necessary, by inserting strips of bare cable into the tube.

- The sleeve is crimped using special press jaws. This is done near both ends and in different directions. If the cross-section of the sleeves is larger than 120 mm², the cable connector is pressed with a tool with a hydraulic drive.

The wire joint that is obtained with special crimping sleeves must be insulated.

Soldering or welding

The reliable connection of wires in an electrical network is achieved by welding them together. The result is a solid conductor that does not oxidize, has minimal resistance and eliminates short circuits.

How to connect wires properly by welding:

- The conductors are stripped of their insulation, and the cores are sanded with sandpaper until shiny;

- Connect the wires by twisting;

- fill the flux into the recess of the carbon electrode;

- turn on the welding machine (24 V, minimum power - 1 kW), press the electrode to the welding spot, hold until a contact point is formed in the form of a ball;

- clean the flux off the welding spot, coat the contact point with varnish;

- insulate the connection.

The same results are obtained by soldering of wiring connections. It is carried out similarly to welding. The difference:

- in the use of solder, which is melted with a soldering iron;

- the obligatory filling of the twist inside with solder.

Soldering connects cables reliably, but the method is not effective:

- When the cables are exposed to heat;

- When the connections are subjected to mechanical stress.

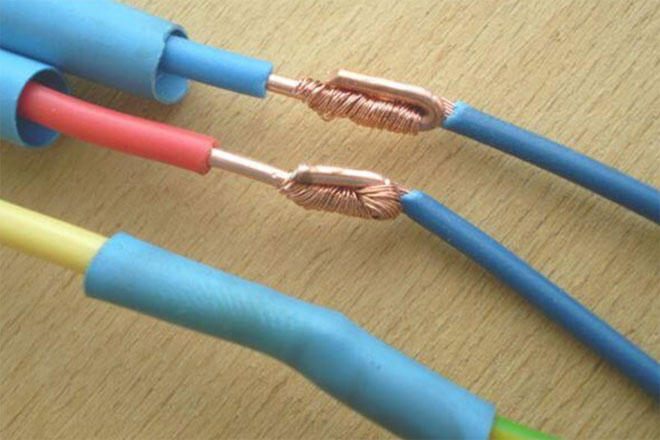

Twisting and Insulation

The twisting method is the simplest of conductor connections. It is used when connecting aluminum wires to each other or others but of the same material. It is considered unreliable, so it is forbidden in the construction of electrical networks. Deciding the question of what is better for the formation of the network Wago terminals or twisting, give preference to the first option.

How to correctly twist wires:

- Remove the insulation on the ends of conductors with a knife;

- grasp the ends with pliers and, holding the cables with the other hand, make 3-5 twisting motions;

- the strands are covered with insulation.

Nut clamp

Clamps for wires with this name have a cube-shaped insulated body, made of polycarbonate. It contains a metal core, which includes 2 bars with grooves for the wire and the intermediate plate. The latter are clamped together by 4 bolts.

Clips for connecting the wire "nut" provide a reliable connection of cables. They are available for different sizes of the latter - the markings are applied to the surface of the strips.

Using the bolt

Bolt connection of wires is reliable, but has large dimensions, which is the reason for the impossibility of placing a large number of them in modern junction boxes. It is performed with a bolt, a washer and a nut. The order is as follows:

- Remove the insulation on the ends of the cables to be connected, form rings on these sections;

- put a metal washer on the bolt body;

- put a ring of one of the conductors on it;

- close with a washer from steel;

- put a ring on the next cable;

- put one more washer;

- seal everything with a nut and cover with insulation.

Connecting several wires

This can be done by twisting, but as long as all the cables are of the same metal. Then it is better to close their union with a cap of PPE, soldered, which will increase its reliability and safety.

For such situations, a cable connector in the form of a terminal block provided for single-, double- and multi-row connections is suitable. Several conductors can be connected by 1 bolt.

Connecting conductors of different cross sections

The best for such a variant are considered to be terminal blocks designed to connect cables with different cross-sectional dimensions. Twist and solder, bolt will do.

Connecting multicore and single core products

You can connect multi-core and single-core cables by soldering or bolting. But when choosing what is better - twist or terminal block, you should give preference to the latter. There are types of terminal blocks that are designed for such situations, regardless of the material of the cables.

Related articles: