Frequency converters are used to connect various electric motors and allow to regulate such characteristics as rotor speed, shaft torque and protect from overloads and overheating. Also, such devices make it possible to connect three-phase equipment into a single-phase system without loss of power and overheating of the motor windings.

Contents .

Varieties of frequency converters

Modern frequency converters differ in a variety of circuits, which can be grouped into several categories:

- High-voltage dual-transformer

The principle of operation of such device consists in series transformation of voltage by means of step-down and step-up transformer, frequency conversion by low-voltage converter, as well as smoothing of peak overvoltage at the output by means of sinusoidal filter. The scheme is as follows: the supply voltage of 6000 V is fed to the step-down transformer and its output is 400 (660) V, then it is fed to the low-voltage converter and after changing the frequency is fed to the step-up transformer to increase the voltage to the initial value.

- Thyristor converters

Such devices consist of multilevel frequency converters based on thyristors. Structurally they consist of a transformer (which provides the lowering of the supply voltage), diodes (for rectification) and capacitors (for smoothing). Also multipulse circuits are used to reduce the level of higher harmonics.

Thyristor converters have high efficiency up to 98% and large output frequency range of 0-300 Hz, which is a positive and demanded characteristic for modern equipment.

- Transistor frequency converters

Such frequency converters are high-tech devices, which are assembled on transistors of different types. Structurally, they have transistor inverter cells and multi-winding dry transformer of special design. Such a converter is controlled by a microprocessor, which allows fine-tuning the operation of the equipment and controlling the entire process of various motors. Transistor frequency converters, as well as thyristor converters, have high efficiency and a wide range of frequency regulation.

How to connect a frequency converter

To connect a frequency converter to the equipment, it is first necessary to make sure that the characteristics of such a device are suitable for operation with a particular electric motor. It is also important that the mains voltage allows the use of the frequency converter.

When installing and wiring the frequency converter, it is necessary to ensure that the operating conditions meet the class of protection against moisture and dust, and that all distances from moving parts of machines and mechanisms, from human passages and electrical equipment and apparatus are maintained.

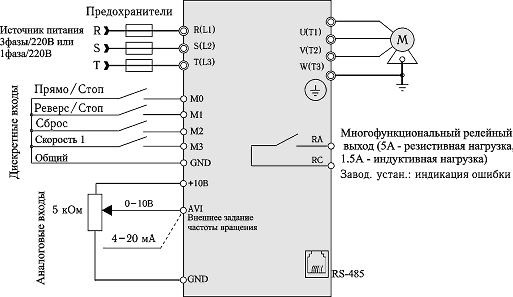

Wiring diagram of frequency converters

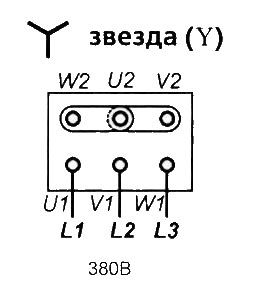

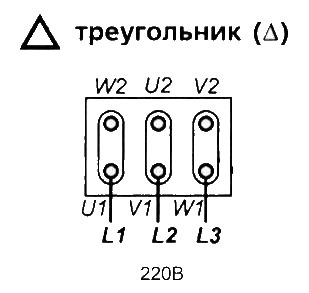

Frequency converters are available for three-phase networks, and for single-phase. In this case, a three-phase frequency converter can also be connected to a single-phase network according to the "delta" scheme, which is additionally equipped with a special capacitor unit (the power is significantly reduced and the efficiency of the unit is lowered). The three-phase inverter is connected to the corresponding network in a star configuration.

The frequency converter can be controlled using contactorsThe frequency converter can be controlled using contactors integrated in various relay circuits, microprocessor controllers and computer equipment, as well as manually. Therefore, when connecting automated systems requires the participation of specialists in the adjustment of such equipment.

Please note! Frequency converter can have additional settings carried out with the help of DIP-switches, as well as with the built-in software.

The principle of connection of frequency converters is generally the same, but may differ slightly for different models. Therefore, the right decision is to study the manual before connection, compare the characteristics of the devices and make sure that the device is connected according to the diagram suggested by the manufacturer.

For a three-phase electric motor

For a three-phase motor, the connection principle is as follows: Phase conductors are connected to the terminal blocks at the output of the three-phase frequency converter to each terminal, and the phases of the supply voltage are connected to the input. In this case, the "star" connection scheme in the motor is always implemented. When connecting a three-phase motor through a frequency converter to a single-phase network, a "delta" circuit is applied.

For single-phase motor

For Single-phase motor you need to connect the phase and neutral conductors to the frequency converter and the motor windings are connected to the corresponding terminals on the output of the frequency converter. For example, winding L1 would be connected to terminal A of the inverter, winding L2 to terminal B, and the common wire to terminal C. If a capacitor motorIf the frequency converter is connected to the motor, the phase is connected to the motor and a capacitor provides the phase shift.

In all cases, when connecting frequency converters and electric motors, you should always use protection devices: circuit breakers and RCDs, designed for high inrush currents, as well as be sure to connect the grounding conductor to the housings of devices. It is also important to pay attention to the cross section of electrical cable conductors, which will be connected - the cross section must match the parameters of the connected frequency converter and the load.

Related articles: