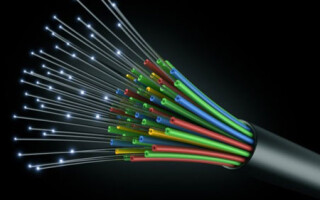

Fiber optic cables are widely used today to transmit data. In some areas of IT, they have completely replaced traditional lines of communication based on metallic conductors. Fiber-optic lines are especially effective where large amounts of data must be transmitted over long distances.

Contents

Physical basis of fiber optic cables

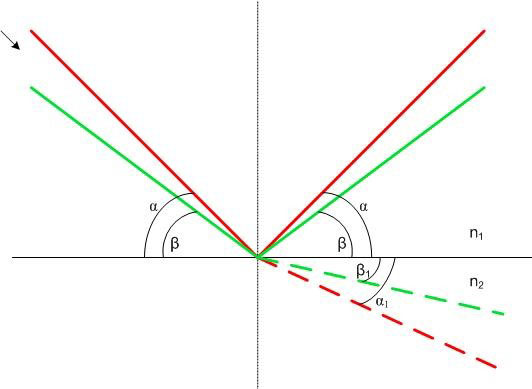

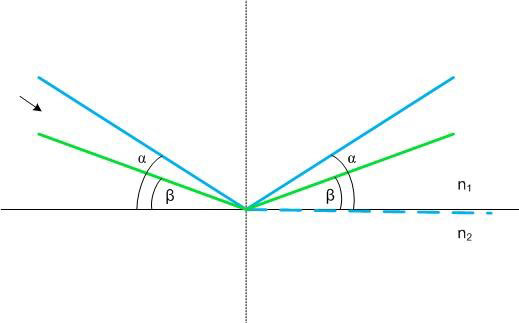

The physical principles of optical fiber are based on the principle of total reflection. If we take two media with different refractive indices n1 and n2, with n2< n1 (e.g., air and glass or glass and transparent plastic) and send a beam of light at an angle α to the interface, two events will occur.

The ray (marked in red in the picture), which is launched from above from the left (along the arrow) will be partially refracted and will follow the medium with refractive index n2 at an angle α1<α - this part of the beam is indicated by the dashed line. The other part of the beam will be reflected from the interface at the same angle. If we let the beam under a more gentle angle β (the green beam in the figure), the same thing will happen - partial reflection and partial refraction under the angle β1.

If the incidence angle α is further reduced (blue beam in the figure), then one can achieve that the refracted part of the beam "slides" practically parallel to the interface (blue dashed line). Further reduction of the angle of incidence (green ray falling at an angle β) will cause a qualitative jump - the refracted part will be absent. The beam will be completely reflected from the interface between the two media. This angle is called the angle of total reflection, and the phenomenon itself is called total reflection. The same will be observed when the angle of incidence decreases further.

Construction of an optical fiber

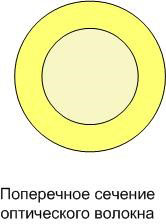

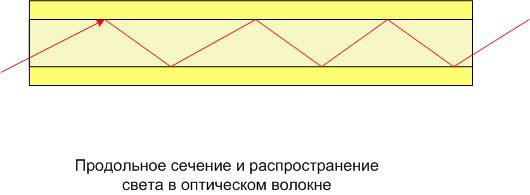

This is the principle upon which optical fibers are built. It consists of two coaxial layers with different optical densities.

If a light beam enters the open end of the fiber at an angle larger than the angle of light reflection, it will be reflected from the contact boundary between two media with different refractive indices completely, with little attenuation at each "jump".

The outer part of the fiber optic is made of plastic. The inner can also be made of transparent plastic, then it can be bent at fairly large angles (even twisted into a ring, and the light that gets inside will still pass from one end to the other with attenuation, depending on the optical properties of the plastic and the length of the fiber). For long distance cables, where flexibility is not so important, the inner core is usually made of glass. This reduces the attenuation, reduces the cost of the light fiber, but it becomes sensitive to bends.

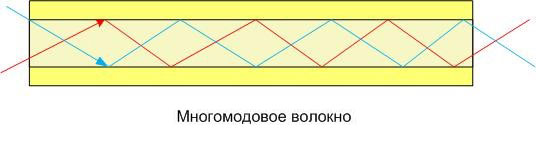

To increase the capacity of an optical line, the fiber is produced in a dual-mode or multi-mode version. For this purpose, the core cross-section is increased to 50 µm or 62.5 µm (versus 10 µm for single-mode). Two or more signals can be transmitted simultaneously through such a light guide.

This construction of the optical transmission line has certain disadvantages. One of them is the light dispersion caused by the different route of each signal. They have learned to fight it by making a core with a gradient (changing from the middle to the edges) refractive index. Due to this the routes of different beams are corrected.

This construction of the optical transmission line has certain disadvantages. One of them is the light dispersion caused by the different route of each signal. They have learned to fight it by making a core with a gradient (changing from the middle to the edges) refractive index. Due to this the routes of different beams are corrected.

Cables with multi-mode fibers are mostly used for local networks (within one building, one company, etc.), and with single-mode - for trunk lines.

Design of a fiber optic line

A fiber optic line transmits a light signal produced by an LED or laser. An electrical signal is generated in the transmitting device. The final device also needs the signal in the form of electrical pulses. Therefore, it will be necessary to convert the raw data twice. A simplified diagram of a fiber optic line is shown in the figure.

The signal from the transmitting device is converted into light pulses and transmitted over the optical line. The power of emitters on the transmitting side is limited, so devices that compensate the attenuation - optical amplifiers, regenerators or repeaters - are placed at certain intervals on lines of great length. On the receiving side there is another converter that transforms the optical signal into an electrical signal.

Optical Cable Construction

To organize a fiber-optic line, individual fibers are used as part of an optical cable. Its construction depends on the purpose of the transmission line and the method of laying, but in general it contains several optical fibers with individual protective coating (against scratches and mechanical damage). Such protection is usually done in two layers - first a shell of compound, and an additional coating of plastic or varnish on top. The fibers are encased in a common sheath (similar to conventional electrical cables), which determines the application of the cable and is chosen based on the external influences to which the line will be exposed during operation.

When laying in cable trays there is a problem of protection of lines from rodents. In this case it is necessary to choose cable, the outer sheath of which is reinforced with steel tape or wire armor. Also as protection against damage glass fibers are used.

If the cable is laid in the pipe, reinforced shell is not needed. Metal tube reliably protects against the teeth of mice and rats. The outer sheath can be made lighter. This makes it easier to tighten the cable inside the pipe.

If the line will be laid in the ground, protection is performed in the form of wire armor, protected from corrosion, or fiberglass bars. Here, high resistance is provided not only to compression but also to stretching.

If the cable must be laid on the sea, through the rivers and other water obstacles, marshy ground, etc., additional protection is used from aluminopolymer tape. In this way safety against water penetration is carried out.

Also, many cables inside the overall sheath contain:

- reinforcing rods that serve to give the structure greater strength under external mechanical influences and thermal elongation of the line;

- fillers - plastic threads that fill up empty areas between fibers and other elements

- power rods (their purpose is to increase the tensile load).

In long spans the line is suspended on a cable, but there are self-supporting cables. The supporting metal cable is built directly into the sheath.

As a separate type of fiber-optic line should be mentioned optical patch cord. This cable contains one or two fibers (single-mode or dual-mode) encased in a common sheath. Both sides of the cord are equipped with connectors for connection. These cables are short in length and are designed for connecting equipment over short distances or laying in-cabinet communications.

Advantages and disadvantages of optical cables

The undoubted advantages of optical cables, which determined the widespread use of such communication lines, include:

- high noise immunity - the light signal is not affected by domestic and industrial electromagnetic radiation, and the line itself does not radiate (this makes unauthorized access to the transmitted information difficult and does not create problems of electromagnetic compatibility);

- complete galvanic isolation between the receiving and transmitting side;

- low level of attenuation - much less than that of wire lines;

- long lifetime;

- high bandwidth.

In today's realities, it is also important that the cable does not attract metal thieves.

Optics is not without its disadvantages. First of all it is a complexity of installation and connection, which requires special equipment, tools and materials, as well as imposes higher requirements to skills of the personnel, involved in installation and maintenance of lines. Most failures in FOCL are associated with errors in installation, which may not manifest themselves immediately. Initially, the cost of the line itself was also high, but the development of technology made it possible to reduce this disadvantage to competitive levels.

Optical communication lines have occupied a serious sector in the market of communication materials. There is no serious alternative to them in the foreseeable future, unless there is a technological breakthrough.

Related articles: