The refrigerator represents that technics without which it is very difficult to manage in household conditions. That is why its malfunction often results in a certain discomfort. In this case there can be both the usual breakdowns, when the refrigerator refuses to turn on, and the opposite cases. Quite often a household appliance, on the contrary, does not switch off when it is necessary and works without interruption. What leads to the violation of the normal mode of functioning? Why the refrigerator does not turn off, but most importantly, what can be done?

The contents of .

Main causes of refrigerator malfunction

The operation of any refrigeration equipment is based on cyclicality - that is, it is turned on, and after some time there is a scheduled shutdown. And so it goes on and on. The ratio between these intervals depends on the ambient temperature and the selected cooling mode. Usually, the compressor runs for 10-20 minutes, based on external conditions.

Continuous operation of the power unit is not properly fraught with overheating later and increased wear and tear of parts. Refrigerators with different technical equipment are available for sale, but no matter how modern the model may be, it is in no way designed for long engine operation without stopping it.

Such an essential attribute consists of many parts, and therefore the reason why the refrigerator does not work properly can be a breakdown of any of them. Some problems can be solved by the owner of the equipment himself, but in other cases it will be necessary to call a master at home for professional diagnostics.

No Frost system

Equipment with such equipment is no longer rare, and many owners purchase exactly such equipment. If before the old household appliances had to be periodically turned off to get rid of icing, the modern units do not need this. Unless it's for major cleaning inside.

But even this system sometimes experiences the same problems - the refrigerator runs at full capacity and all the time. In this case, the malfunction can be of two types:

- Long running after putting food in or opening the refrigerator compartment door or freezer.

- The compressor runs much longer than it should.

In the first case, the cause is a blowing problem. On the back wall there is usually a fan (depending on the model there may be several), which disperses the air through the main and the freezer compartments. Its failure leads to a disturbance of the cooled flow circulation mode. The fan itself may break or freeze.

Outside (in the evaporator compartment area) the air is cold, but it is warmer inside the chamber. The temperature sensor detects the value and sends a signal to cool, which makes the compressor work harder.

To make a diagnosis is not difficult - it is enough to remove the back panel (it is usually made of plastic). Here you can see the evaporator with fans (if there are several). It is worth turning on the refrigerator and see if they work.

The second case concerns the sensor-compressor system, when there is a continuous signal from the sensor and the compressor works hard without stopping. There are reasons for this:

- Evaporator icing;

- The fan is broken;

- The "Super Frost" mode has been activated;

- Temperature device malfunction;

- The freon line is damaged.

It is possible to get to the evaporator compartment by yourself - it is enough to remove the back wall. Depending on the refrigerator model, it may be necessary to remove the side covers. And if the check does not give an answer to the question and the appliances are still working with wear and tear, it is worth to call a master.

Damaged door seal

This is a common cause of why the refrigerator keeps running and won't shut off. The rubber element is located around the entire perimeter of the door and prevents cold air from leaking out of the internal chambers. However, over a long period of use, the seal cracks, begins to peel off, or even bursts. This leads to depressurization, and the heat flow rushes inside.

As a result, the compressor begins to work harder - that is, it tries its best to compensate for the excessive heat from the outside. Even a small hole promises quite serious problems in the future. This makes it seem that the equipment stops freezing, although this is not true.

"Trouble" is easy to fix - it is enough to find such a seal and carefully fix it on the door. Everyone is able to cope with this work.

Mounting the seal

There are several ways to fix the door element:

- Polymer glue - the composition retains its properties even in conditions of low temperature. This is a universal solution.

- Special grooves - some models have special technological protrusions, as well as notches. It is better to buy a rubber gasket from the manufacturer of the equipment, which simplifies its installation. However, native gaskets are expensive, sometimes you have to buy Chinese analogues of low quality, but they are noticeably cheaper. Sometimes even this variation can last as long as the original.

- Self-tapping screws are a barbaric mounting method. But since there is a wide range of polymer adhesives on sale, these fasteners are no longer used to mount the sealant. In addition, it is impossible to guarantee complete sealing.

The exact method of attaching the sealant depends on the model of the refrigeration unit.

Set point error

Often the cause of compressor malfunction is an incorrectly set thermostat. The temperature inside the main chamber must be kept constantly between 0° and 5° Celsius. This mode slows the development of microorganisms. At the same time, places are formed where each has its own parameter. If you put the food in the wrong place, it will freeze.

The optimal temperature distribution is as follows:

- for vegetables, fruits and herbs - +7 °C (lower compartment);

- for meat and fish: +2 °Clower shelf above the containers);

- for dairy products, eggs, soups - +4 °C (middle shelves);

- for side dishes, jams - +7 °C (top shelves).

On the door shelves the temperature is usually around +10 °C. Here we recommend storing drinks, concentrates, ready made sauces.

Compressor failure

Each refrigerator is equipped with a relay and thanks to this part sets its cycle. Sometimes the contacts stick to each other, and at the right time can not disengage. Then the compressor starts to work non-stop, and if it does turn off, it does it rarely. In other cases, the reason lies in natural wear and tear, and then the system doesn't build the right pressure, which causes it to fail to reach the desired temperature. The result is already clear.

It is possible to correct the problem by replacing the motor. And this work should only be done by a specialist, since it involves several stages:

- disassembly of the refrigeration unit is required;

- installation (replacement) of the motor;

- It is necessary to re-inject freon into the system;

- Start-up procedure of temperature sensor;

- Carrying out of testing and commissioning works.

The cause of the problem should be necessarily established, otherwise buying a new compressor will turn out to be the same trouble. Therefore, here you can not do without calling a master.

The room temperature is too high

Another common reason, which indicates inattentiveness of the owners. Do not be surprised by the appearance of trouble when the refrigeration unit is located near heating appliances (pipes, radiators, heaters, fireplaces) or on the sunny side. Do not place the unit in these areas!

To avoid overheating of the motor you should follow a number of simple rules:

- Do not place the refrigeration equipment in front of a window opening;

- Do not place the appliance on a warm floor;

- Always close the door tightly;

- Ensure optimal ventilation in the kitchen.

It is better to move the refrigerator to a suitable place where it will not get warmer than +10°C. It is also worth installing an air conditioner in the kitchen to create a pleasant atmosphere during the hot season.

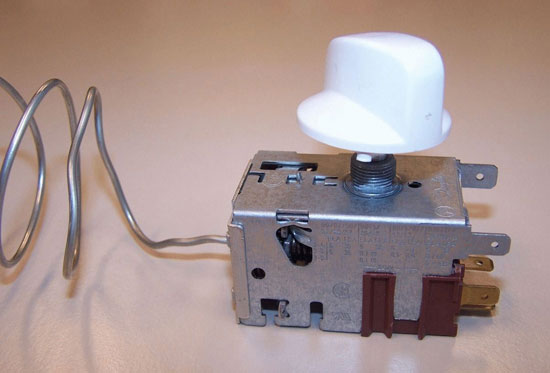

Thermostat is out of order

When the part is working properly, the refrigerator's cycle of operation is smooth. However, its failure leads to the fact that the compressor does not turn off at the right moment and continues to work at the wear and tear.

To diagnose it, the following algorithm will help:

- remove the back of the refrigerator;

- remove the temperature sensor;

- there is a plate near the central nut - press it;

- If there is no click - the part needs to be replaced.

It is also possible to identify the problem in another way. To do this, it is worth comparing the readings of the rated power of the equipment (it is given in the manual) and the current electricity consumption during the day. This is usually 30 kW per month. If the energy consumption deviates from the norm to the higher side, you can conclude that the thermostat is defective.

If the refrigerator does not turn off, constantly working, how to fix it then? The problem is solved by installing a new part, which is also on the power of any owner of technology.

Broken evaporation tubes

These tubes directly affect the operation of the cooling system. The main cause of their failure is an ice clot due to engine malfunction or loss of tightness. The cause of these breakdowns is as follows:

- Overheating - The compressor generates a lot of heat during operation and often generates a higher temperature for which the sockets are not designed. As a result, their tightness is compromised.

- Contamination - There is only refrigerant and oil circulating inside the cooling circuit, nothing else should be there. Air, moisture, dirt, dust and other contents are contaminants that adversely affect the operation of the compressor. These can be caused by poorly maintained equipment.

- Lack of lubrication - leads to increased wear of the motor, which sooner or later ends with its overheating. The pipes also risk getting more heat than necessary.

Here, it is very difficult, if not impossible, to manage on your own. In addition, you need to almost completely disassemble the technique. Therefore, there is only one way out - to call a master or delivery of the refrigerator to a workshop.

The refrigerant is leaking from the system

Freon leakage usually occurs due to wear and tear of the evaporator system. Another reason is improper charging of the refrigerant. Visually, the malfunction manifests itself with oily spots and traces of rust on the walls.

Also freon leaks due to kinks in pipes. To fix the problem, you need to refill the system with freon. But this work should only be done by a specialist.

Malfunction in the control module

Any modern refrigerator is equipped with a complex electronics system for protection against power fluctuations, short circuits and other troubles. The correct operation of the equipment depends on the operability of the control module. And if it starts to malfunction, problems occur with the refrigeration unit. As a rule, it happens due to the breakdown of its contacts.

The existing problem is eliminated by re-flashing the control module, which only a master can do.

Breakdown in single-compressor models

Older models of refrigeration units use a single motor that takes on the entire load of cooling both chambers. Therefore, such compressors are more likely to break down. At the same time, in each particular model of equipment malfunctions can be individual in nature. For example, Liebherr refrigerators cannot withstand an outside cold snap at +16˚C or less, or a temperature rise over 32 degrees. As a result, the thermostat fails, causing the power unit to malfunction.

Prolonged freezing causes Nord refrigerators to have faulty starting relays and temperature sensors. Atlant refrigerators more often break down thermoregulators and defrost sensors due to increased external temperature conditions.

Refrigeration units with one compressor need frequent repair and service in the service center.

Instances where uninterrupted operation is not a breakdown

Sometimes uninterrupted operation is in no way related to a malfunction. This happens in a number of cases:

- after transportation;

- After completion of defrosting;

- Due to voltage fluctuations;

- Incorrect operation - often with a door that is not properly closed.

That is, when the refrigerator runs without interruption after defrosting, it is due to the need to bring the temperature in the refrigerator to the desired value. Sometimes it takes several hours for this, then the compressor starts to operate in cyclic mode. Often the sound of the fans motor is mistaken for the noise of the power unit of the fridge. And it is possible to think that it is the compressor that starts humming.

The conclusion .

Lovers of fixing everything on their own should take into account that to fix some malfunctions you need to have the appropriate skills and experience in owning the right tools. Only then the repair of the refrigerator can be done without mistakes, and the unit will again work in full force. Otherwise, it is better to turn to the professionals of the service center.

Related articles: